Get custom metal and plastic 3D printed prototypes

and production parts from as fast as 1 day!

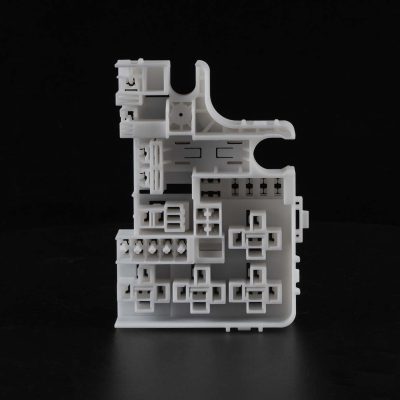

HLH offers a wide range of in-house custom metal and plastic 3D printing services, enabling us to deliver printed parts in all forms,

complexity and size, and fitted for different functions and applications.

| SLA | SLS | DMLS / SLM | FDM | MJF | |

|---|---|---|---|---|---|

| Max build size (in mm) | 800 × 800 × 550 | 400 × 400 × 450 | 280 × 280 × 280 | 750 × 750 × 750 | 294 × 211 × 144 |

| Max build size (in inches) | 31.5 × 31.5 × 21.6 | 15.7 * 15.7 * 17.7 | 11.0 × 11.0 × 11.0 | 29.5 × 29.5 × 29.5 | 11.6 × 8.3 × 5.7 |

| Lead times from | 2 days | 2 days | 4 days | 1 day | 3 days |

| Layer thickness | 50–100 μm (0.05–0.1 mm) | 100 μm (0.1 mm) | 20–80 μm (0.02–0.08 mm) | 200 μm (0.2 mm) | 80 μm (0.08 mm) |

| Prototyping applications | High detailed parts with excellent surface quality | Durable parts for form, fit and function testing | Metal prototypes with complex geometries | Quick proof of concept models | Functional and high-fidelity prototypes |

| End-use applications | Aesthetic parts with high resolution for indoor applications | Batch production of functional, high strength parts | Functional and lightweight metal components | Spare parts and jigs and fixtures | Higher volume production and functional parts |

| Quantity | 1–500 | 1–10,000 | 1–1,000 | 1–1,000 | 1–50,000 |

| SLA service | SLS service | DMLS service | FDM service | MJF service |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

All parts are made in-house in our factory in China, with small-scale 3D printing in the UK. We use industry-leading equipment to deliver prototypes and end-use parts with precision and speed for engineers worldwide.

| High performance | PPSF/PPSU, PEI ULTEM 1010, PEI ULTEM 9085, PAHT-CF, PA12GF |

| Mechanical parts | PA12, PA12GF, ASA, SS316L, AlSi10Mg, PEI (Ultem 1010, 9085), PPA, PAHT-CF, PPS, PPS+CF, PPS+GF |

| General-purpose | PA12, PLA, ABS-like, PBT-like |

| Metal | Aluminium, Stainless Steel, Copper |

| Transparent | PMMA-like, PC-like, Clear ABS-like |

| Rubber-like | TPU 85A, TPU 92A, TPU 95A |

| Lower cost | PLA, ABS |

| Other properties | Flame retardant PLA, flame retardant ABS, ABS anti-static, PETG anti-static |

Due to the additive nature of the process, 3D printing allows for higher freedom of design than traditional manufacturing methods. To take full advantage of the technologies available at HLH, design your 3D model for the process.

| SLA | SLS | DMLS / SLM | FDM | MJF | |

|---|---|---|---|---|---|

| Technology | Resin Based | Powder Bed Fusion | Powder Bed Fusion | Filament Based | Powder Bed Fusion |

| General tolerance | ±0.2 mm | ±0.3 mm | ±0.3 mm | ±0.5 mm | ±0.3 mm |

| Requires support structures | YES | NO | YES | YES | NO |

| Minimum recommended wall thickness | • Supported: 0.5 mm • Unsupported: 0.8 mm | • Supported: 0.8 mm • Unsupported: 1 mm | • Supported: 1.2 mm • Unsupported: 1.5 mm | • Supported: 1.0 mm • Unsupported: 1.2 mm | • Supported: 0.75 mm • Unsupported: 1.0 mm |

| Embossed text | Min.: 0.3 mm | Min.: height 1 mm | Min.: height 0.3 mm | Min.: height 0.3 mm | Min.: height 0.5 mm |

| Engraved text | Min.: depth 0.5 mm, width 0.5 mm | Min.: depth 1 mm, width 1 mm | Min.: depth 0.5 mm, width 0.5 mm | Min.: depth 0.5 mm, width 0.5 mm | Min.: depth 1 mm, width 1 mm |

| Minimum mating parts clearance | 0.5 mm apart | 0.5 mm apart | 0.4 mm apart | 0.5 mm apart | 0.9 mm apart |

| Advantages | • Optimal for aesthetic and large parts • Injection-mould-like smooth finish • Wide range of resins available | • No support structures required • Fantastic for high-strength, functional parts • Optimal for snap-fit connectors and batch production | • Short lead time for metal production • Great for lightweight, functional metal parts • Excellent for creating complex metal parts | • Quick print time • Industrial FDM can print large parts • Variety of filaments available | • No support structures required • Fantastic for high-strength, functional parts • Optimal for snap-fit connectors and batch production |

| Disadvantages | • Sensitive to UV light, will deform and yellow • Generally less durable though engineering-grade resins are now available | • Rough/grainy finish • Inaccessible areas and confined hollow cannot be cleaned of excess powder | • Rough, porous finish • Can be costly • Requires extensive post-processing | • Lower resolution • Visible layer lines • Not suitable for intricate details | • Machine builds are smaller than SLS • Inaccessible areas and confined hollow cannot be cleaned of excess powder |

| View SLA design guide | View SLS design guide | View DMLS design guide | View FDM design guide | View MJF design guide |

Yes, it’s possible. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) machines, like the ones we use at HLH, are designed for 3D printing high-quality, precision metal parts. These technologies can build parts from a wide range of metal alloys, including aluminium, stainless steel, copper, bronze, titanium, and nickel-based superalloys.

While PLA and PETG are often certified as food-grade materials, we do not recommend 3D printing for food containers or other food-safe applications. Even with certified filaments, the printing process and post-processing can introduce risks—such as contamination from printer nozzles, chemical degradation due to high extrusion temperatures, and potential chemical interactions—making printed parts unsafe for direct food contact.

In manufacturing you’re only as good as your last order, so we take quality seriously.

Once completed, your 3D printed parts are transferred to the quality control (QC) department for inspection. We include a comprehensive, standardized inspection report with every order to ensure quality metrics are being met. We also have multiple certifications available on request, including ISO 9001, ISO 14001, ISO 27001, ISO 13485 and IATF 16949.

The unit price of 3D printing can range from just $1.20 to several hundred, depending on factors such as material, print time, part weight, printer type and design complexity. Metal 3D printing is generally more expensive due to the higher material cost, specialized machinery, and the longer, more labor-intensive post-processing it requires. Check out our article on how manufacturers estimate 3D printing costs.