In the context of rapid prototyping, carbon fiber is revolutionizing manufacturing processes, offering a unique blend of speed, efficiency, and high-quality output. Among the materials employed in rapid prototyping, carbon fiber stands out for its distinctive properties and advantages. In this article, we will take a closer look at what carbon fiber is, your options for carbon fiber prototyping, its advantages, and considerations.

At its core, carbon fiber is composed of thin, strong crystalline filaments of carbon, that are used to reinforce other materials, enhancing performance and durability. Today, this composite material is a key component in fields ranging from aerospace and automotive to sports equipment and advanced engineering.

The reinforcement of materials with carbon fiber, known as carbon fiber reinforcement, involves embedding carbon fiber into a matrix (often a plastic polymer) to form a carbon fiber reinforced polymer (CFRP). This CFRP composite material is known for its exceptional strength-to-weight ratio, a crucial factor in many high-performance applications.

Rapid prototyping is a process that transforms digital designs into tangible parts quickly and efficiently. Carbon fiber has become a crucial material in this process, especially for applications demanding parts with superior strength and lightweight. In the rapid prototyping process using carbon fiber, the journey begins with a digital model, usually created using computer-aided design (CAD) software. The model is then brought to life using additive manufacturing techniques, such as 3D printing or selective laser sintering.

At HLH Rapid, there are two ways to make carbon fiber prototypes: prepreg carbon fiber moulding and carbon fiber machining. But additive manufacturing is another way to make carbon fiber parts that has opened new frontiers for manufacturing. In this section, we will take a look into these three carbon fiber prototyping methods.

Prepreg carbon fiber molding enables the creation of complex and intricate shapes and allows for precise control over the orientation of the fibers during the layup process. The process consists of four main steps:

Step 1: Mould tool making. Molds are used as tools to create multiples of the same part. manufactured often from aluminium or steel depending on the quantity of parts required and the tolerances required.

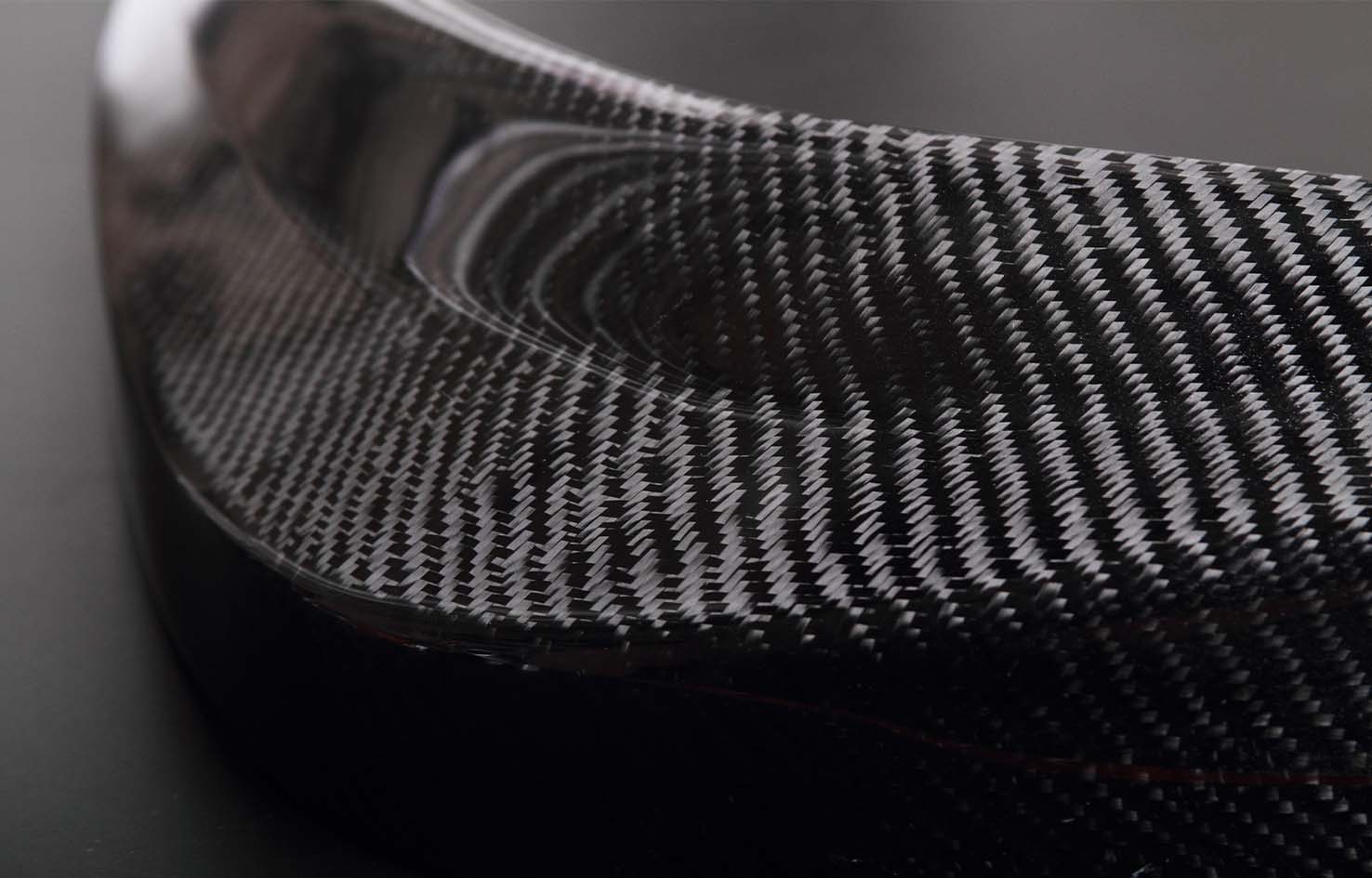

Step 2: Carbon fiber processing. The carbon fibre prepreg sheets are then manually laid by skilled technicians onto the prepared mould surface in a specific orientation and the resin-infused carbon fiber sheets, known as prepreg, are then carefully arranged to achieve the desired characteristics.

Step 3: Curing. Following this the parts are then cured. This step is vital for achieving the desired material properties, strength, and structural integrity of the final carbon fiber composite part.

Step 4: Post processing. Lastly, the parts are post processed. This step is important to achieve professional-looking carbon fiber prototypes. The smoother the mold and the neater the application, the less post-processing required.

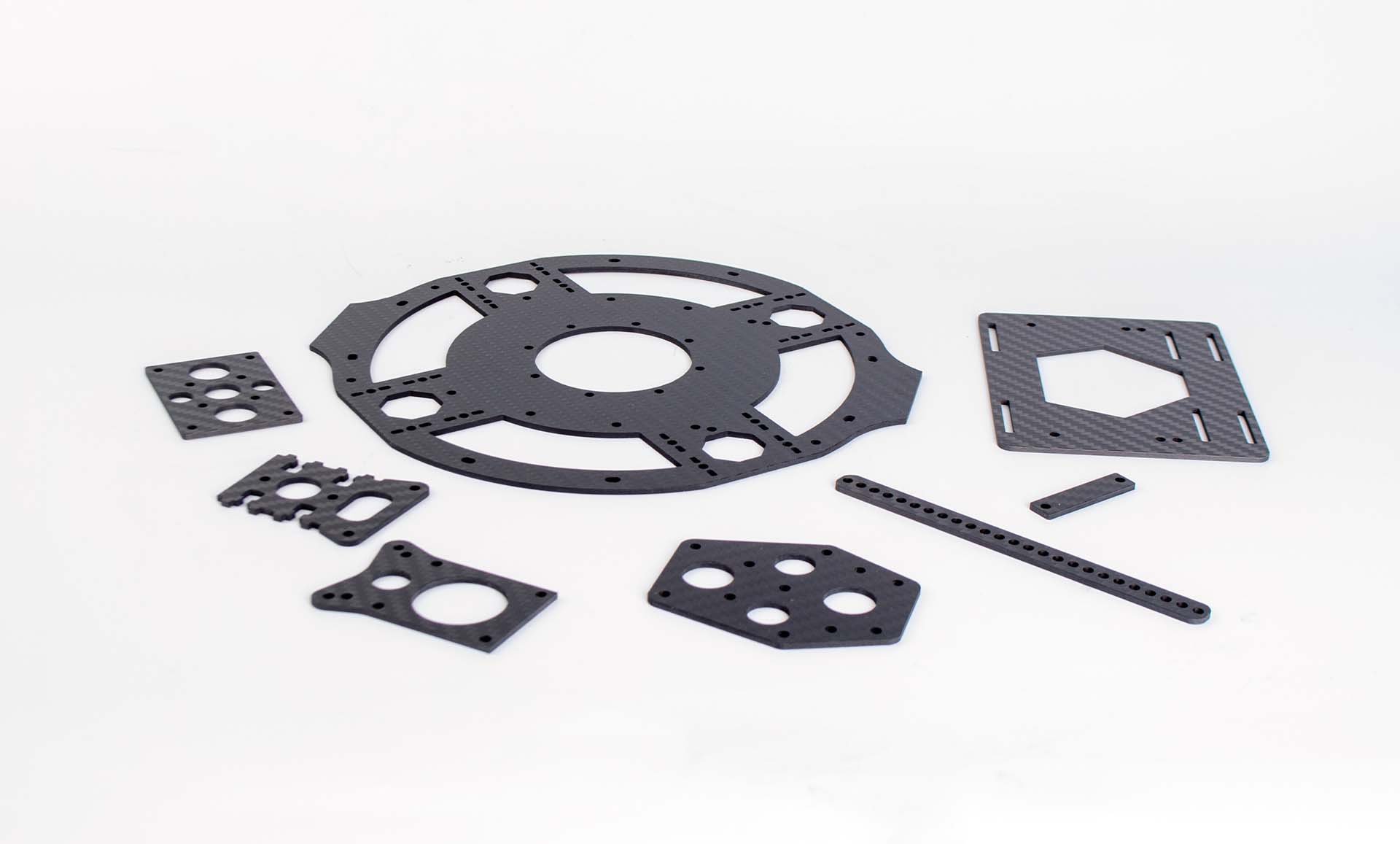

CNC (Computer Numerical Control) technology also plays a role in shaping carbon fiber parts. It is a subtractive manufacturing process, where material is removed from a solid block of carbon fiber or a carbon fiber composite to achieve the desired shape. Machining carbon fiber can be challenging, therefore, working with an experienced manufacturer is important.

Carbon fiber because of its low coefficient of thermal expansion, there is less warping or distortion during machining, which allows for greater accuracy in dimensions and more consistent results throughout production runs. This makes it particularly useful for creating parts with high precision and a smooth surface finish, such as electronic enclosures and automotive chassis and frames.

3D printed carbon fiber combines the design flexibility of 3D printing with the strength and durability of carbon fiber, offering unparalleled advantages in manufacturing complex and high-strength parts. The process involves using continuous or chopped carbon fiber filaments to form the final shape using an additive manufacturing technology.

Fused filament fabrication (FFF) and continuous fiber fabrication (CFF) are two common carbon fiber 3D printing technologies. In FFF, carbon fiber filaments are extruded through a heated nozzle, layer by layer, to build a part. CFF, on the other hand, embeds continuous carbon fiber strands into a thermoplastic matrix, providing even greater strength and stiffness.

Successful applications of 3D printed carbon fiber are abundant and diverse. In the automotive industry, it has been used to create lightweight, high-strength components that improve fuel efficiency and performance. Aerospace companies leverage it for manufacturing parts that withstand extreme conditions while minimizing weight.

The integration of carbon fiber into rapid prototyping has ushered in a new era in manufacturing, bringing with it a host of unique benefits that set it apart from traditional materials. Understanding these advantages is crucial for industries aiming to stay at the forefront of innovation and efficiency.

Carbon fiber is all about reducing weight while maintaining strength. Due to the high costs of the current processes for manufacturing carbon fiber parts it is important to understand the limitations and what you can do to bring costs down.

Underlying layers are one area you can reduce costs if your end use allows. The distinctive 3K weave pattern is a big draw for choosing carbon fiber, but these are more expensive than UD sheets or fiberglass which can be used as the bottom layers with a 3K top sheet.

Fine, sharp features can be difficult to reproduce, so ensure there are sufficient radii on the part to allow the fabric to follow the contour easily.

We have in-depth experience manufacturing composite parts to very high quality and repeatability via prepreg carbon fiber and carbon fiber machining. To get a quote for your rapid carbon fiber protoyping project, send us your drawings and project details to our contact form, and our team will get back to you within 24 hours.