Casting and Machining are two of the most popular methods for producing metal parts. What’s the best way to make metal parts? In this article, we’ll explain how each process works, compare them, and discuss scenarios in which one method might be better suited than the other.

Metal Casting is a formative manufacturing process that involves creating a mould (or die, in some cases) to make a part. First, a mould is created; molten metal is then poured into the mould and allowed to cool and solidify completely to form the desired shape. There are many different metal casting techniques that can be used depending on the material choice, part size, complexity and various other considerations. Some of the most popular casting methods include die casting, sand casting and investment casting.

Example of Steel Moulds Used in Die Casting

Casting is an excellent way to make complex and detailed parts that would be difficult or uneconomical to make via other methods. It is reliable, accurate and perfect for production parts.

CNC<Machining is a subtractive manufacturing process where material is precisely removed from a workpiece using pre-programmed software and a variety of cutting tools to create the desired part. CNC (Computer Numerical Control) encompasses several machining methods, including traditional processes like CNC turning, milling, drilling, and boring, as well as advanced techniques like laser cutting, wire EDM (Electrical Discharge Machining), and abrasive waterjet cutting.

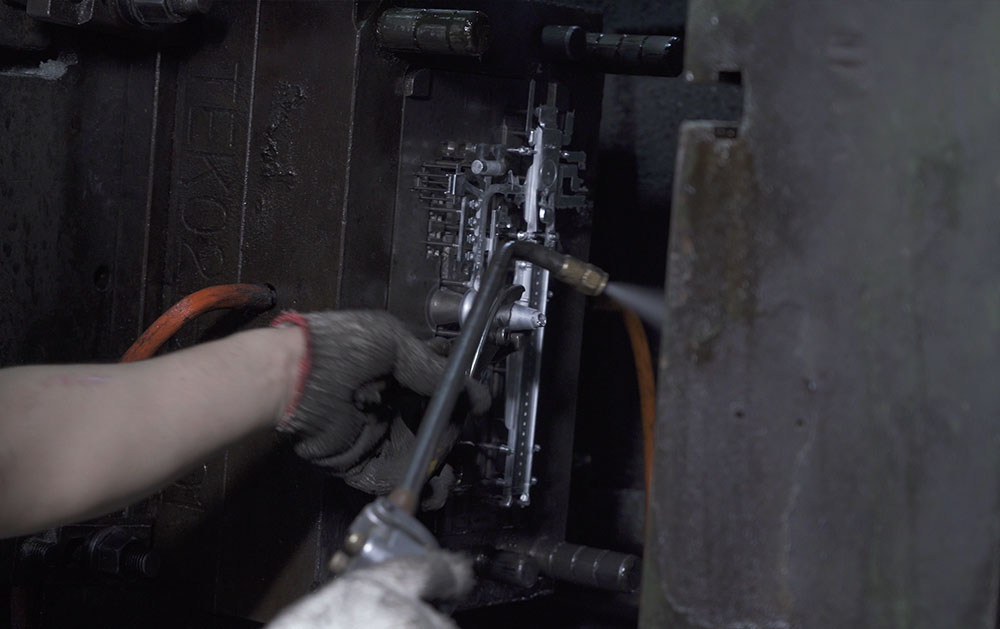

Example of Mould Tool Being CNC Machined

CNC Metal or Metal Machining is an efficient method for producing one-off prototypes as well as batches ranging from a few dozen to several thousand parts. This process delivers highly precise and accurate components, making it ideal for both prototyping and end-use parts.

Choosing between casting and machining can be challenging. Below are several considerations for when casting is better suited than machining, and vice versa.

Repeatability is important in manufacturing, and the casting process is capable of producing very complex shapes consistently and accurately. Once the mould and process are fine-tuned, each part can be made exactly the same. Metal machining is also an extremely repeatable and highly precise process, capable of producing much tighter tolerances than casting. In fact, the precise cavities and features in die-cast moulds are often machined using CNC equipment.

CNC machining is the better choice for rapid prototyping, as it doesn’t require preparatory tooling in the way that casting methods do. It’s therefore more affordable to machine a one-off or small batches of metal parts than to invest in an expensive mould. CNC also provides greater flexibility if design changes and modifications are needed, along with the ability to create parts from an impressive variety of metals.

Casting techniques like sand casting are a good choice for quick prototypes but are limited to simple designs. Although investment casting is a good alternative to sand casting for more complex and detailed designs, it is often more costly and time-consuming than machining.

Machining has the advantage when you need small volumes of parts quickly. As volume increases, casting becomes more efficient and economical. Casting methods like die casting can produce complex shapes with accuracy and deliver higher volumes of parts far more quickly than machining. With casting, post-processing efforts and post-assembly steps are often minimised as well. This faster production cycle makes die casting more reliable for producing large batches.

Material selection for casting is very good, but not as impressively vast as it is for machining. CNC machining can accommodate a wide range of metals. When specific material grades or mechanical properties are called for, like Titanium alloys or certain tool steels, CNC machining may be necessary.

The table below summarizes the key comparisons of casting vs machining.

| Casting | CNC Machining | |

|---|---|---|

| Types | Die Casting, Investment Casting, Sand Casting, Gravity Die Casting, etc. | CNC Milling, CNC Turning, Wire EDM, Laser Cutting, etc. |

| Speed | Much quicker for high-volumes of parts. | Much quicker for 1-off and small batches of parts. |

| Typical Lead Time | From 3 weeks | From 4 days |

| Cost | Initial costs can be high. For large production runs, the cost per part is relatively lower. | Can be cost-effective for low-to-mid production runs. No tooling costs but the cost per part is typically higher. |

| Typical Price Range | $5 | |

| Materials | Zinc, Magnesium, Aluminium | Aluminium, Steel, Stainless Steel, etc. |

| Pros |

|

|

| Cons |

|

|

| Quantity | Typically used for mid-to-high volume production (500-100,000+) | Typically used for low-to-mid batch quantities (1-10,000+) |

Upload CAD, get a quote within 24 hours or less

At HLH, we can manufacture simple and complex metal parts via our CNC Machining and Casting Services. To get started on your next custom metal part production project, simply submit your 3D CAD along with any project details like material, surface finish or quantity, to our Get-a-Quote Form. Our team will get back with a comprehensive quote within 48 hours or less.