There are various ways to make metal cast parts. The three most common techniques include die casting, investment casting, and sand casting. While each is a distinct process, they also share many similarities, which can make choosing a method challenging. In this article, we will provide an overview of each metal casting method, along with their benefits, limitations, and ideal applications.

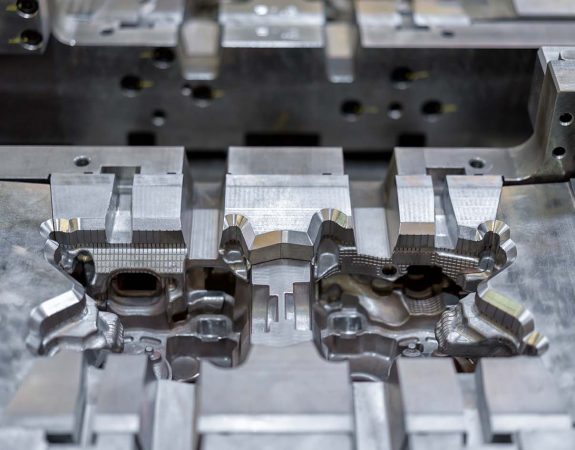

Die Casting is a metal casting technique that involves creating a mould or ‘die,’ installing it on a die casting press and injecting molten metal under high pressure into the tool cavity. Die casting is commonly used to create complex, high-precision parts with fine detail and a good surface finish. Although the upfront cost of creating the mould—typically from steel—can be very high, the mould can be reused for large quantities of parts, making the initial investment worthwhile.

Die Casting Advantages

Die Casting Disadvantages

Investment casting is a metal casting technique that involves pouring molten metal into a hollow, hard ceramic mould to form the desired part. It is ideal for producing complex-shaped components that require tighter tolerances and thinner walls. Investment casting uses a single-use mould that is broken and discarded after each part, resulting in parts with no parting lines. However, the nature of the process makes it less efficient for high-volume production.

Investment Casting Advantages

Investment Casting Disadvantages

Sand Casting is a metal casting technique that involves pouring molten metal into a sand mould held together by an inorganic binding agent. Like investment casting, sand cast moulds are single-use and discarded. Unlike die casting, sand casting does not require high-pressure metal injections. These nature of the mould, makes it more cost efficient for low-to-mid volume production.

Sand Casting Advantages

Sand Casting Disadvantages

The table below summarizes the key differences between die casting, investment casting, and sand casting.

| DIE CASTING | INVESTMENT CASTING | SAND CASTING | |

| Cost | Ideal for mid-to-high volume production. | Ideal for low-to-mid volume production. | Ideal for prototyping and low-to-mid volume production. |

| Accuracy | Good dimensional accuracy. | Can achieve tighter tolerances than die casting. | Low dimensional accuracy. |

| Complexity | Great for complex and intricate parts. | Great for complex and intricate parts. | Limited in handling intricate geometries. |

| Cost | Higher tooling costs, lower unit price. | Lower upfront cost than die casting, typically results in a higher per part cost. | Tooling and per unit cost is relatively inexpensive. |

| Lead Time | Quicker production cycle but longer tooling time. | but longer production cycle times. | Quicker and easier tooling process but slower production cycle. |

| Material Compatibility | Not suited for ferrous metals due to high melting temperatures. | Suitable for various metals, including high-melting-point metals | Suitable for various metals, including high-melting-point metals |

| Surface Quality | Good. Often used directly as the final product. Requires minimum post processing. | Excellent. Often used directly as the final product. Requires minimum post processing. | Poor. Typically results in rough, coarse finish. Requires post processing to improve part quality. |

Simply Upload Your CAD to Get a Quote Within 48hrs or Less

At HLH, we make tooling and produce parts in-house for simple to complex metal casting projects. To get started on your next Die Casting, Investment Casting or Sand Casting project, simply submit your 3D CAD along with any project details like material, surface finish or quantity, to our Site Contact Form. Our team will get back with a comprehensive quote within 48 hours or less.