For convenience, an international standard point of reference known as Durometer Shore hardness, consisting of a series of standardized scales, was developed to accurately compare the hardness and stiffness of different materials.

This article covers the durometer hardness scale, how it’s measured, the importance of shore hardness selection, and the most appropriate shore hardness for your part.

Durometer Shore hardness is a measure of the resistance of a material to indentation or penetration by a harder object. It is primarily used to determine the hardness or stiffness of elastomers, rubbers, plastics, and other materials.

Shore hardness is measured using a ‘Shore Hardness’ gauge (Durometer). The measurement process involves pressing a specified indenter firmly against the material being tested. The depth of indentation created by the indenter is then measured or compared against a scale to determine the material’s hardness.

Measuring shore hardness of O-ring in HLH Rapid QC zone

Durometer measurements are expressed using scales, each scale designed for specific types of materials and has its own range of values. Overall, there are about 15 different shore hardness scales, the three most commonly used scales include Shore 00 scale, Shore A scale, and Shore D scale.

Each scale ranges from 0 to 100, with 0 representing the softest materials and 100 representing the hardest. Essentially, the measurement technique and material properties differ from scale to scale. For example, a hardness reading of 30 on a Shore A scale indicates a very different level of hardness compared to a reading of 30 on the Shore D scale. To give you a better idea, refer to the Shore Hardness chart below.

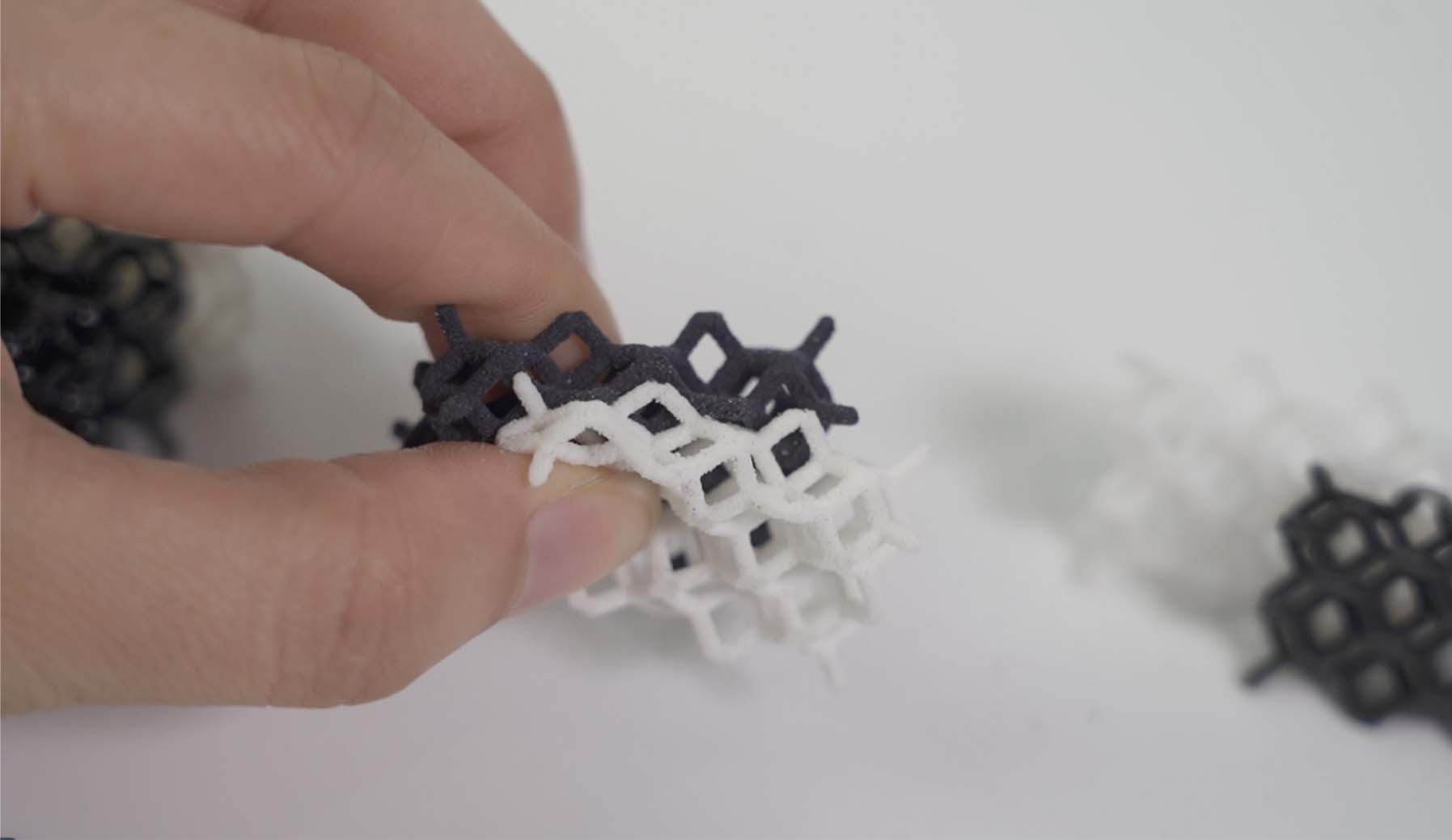

Achieving different Shore hardness values involves using different manufacturing processes, material formulations, and post-processing techniques. Here are some common manufacturing technologies used to achieve different Shore hardness:

The shore hardness of a material affects its performance characteristics, such as flexibility, durability, and resistance to abrasion. Choosing the right shore hardness ensures that parts meet the specific demands of their intended applications, whether it involves sealing, cushioning, absorbing vibrations, withstanding heavy loads, or resisting impacts. Product designers and engineers consistently use this information in conjunction with other material properties to make the best material choice.

For example, in overmolding, the shore hardness of the overmolded material must be compatible with the substrate to ensure proper bonding and adhesion. In the automotive sector, rubber components with specific shore hardness values are essential for sealing integrity, vibration damping, and impact absorption. In the medical sector, the right shore hardness contributes to user comfort, safety, and overall product reliability. Harder polyurethane or plastic materials can also be substituted for metal parts or high-impact-resistant applications due to greater resistance to flex.

Understanding shore hardness selection is also important for extracting models from rubber once it is cured. Although a harder material may seem ideal for these operations, the material can also be more brittle, making it difficult to remove from the mould after curing. For instance, Shore 30A hardness allows manufacturers to more easily remove parts from the mould without damaging thin and delicate parts.

HLH Rapid provides a wide range of manufacturing capabilities and other value-added services for all your prototyping and production needs. This includes the ability to source rubber or plastic parts with different shore hardness levels for prototyping, testing purposes, or higher-volume production.

Simply send us your 3D CAD drawings and project details on our site contact form to get a FREE quote and start your project review.