Injection Moulding is a broad term that covers overmoulding, insert moulding, two-shot (2K) moulding and various other techniques. In this article, we’ll explain the key differences between overmoulding and insert moulding, look at their purposes and applications, explore the pros and cons and provide a practical checklist to help you decide which process is right for your project.

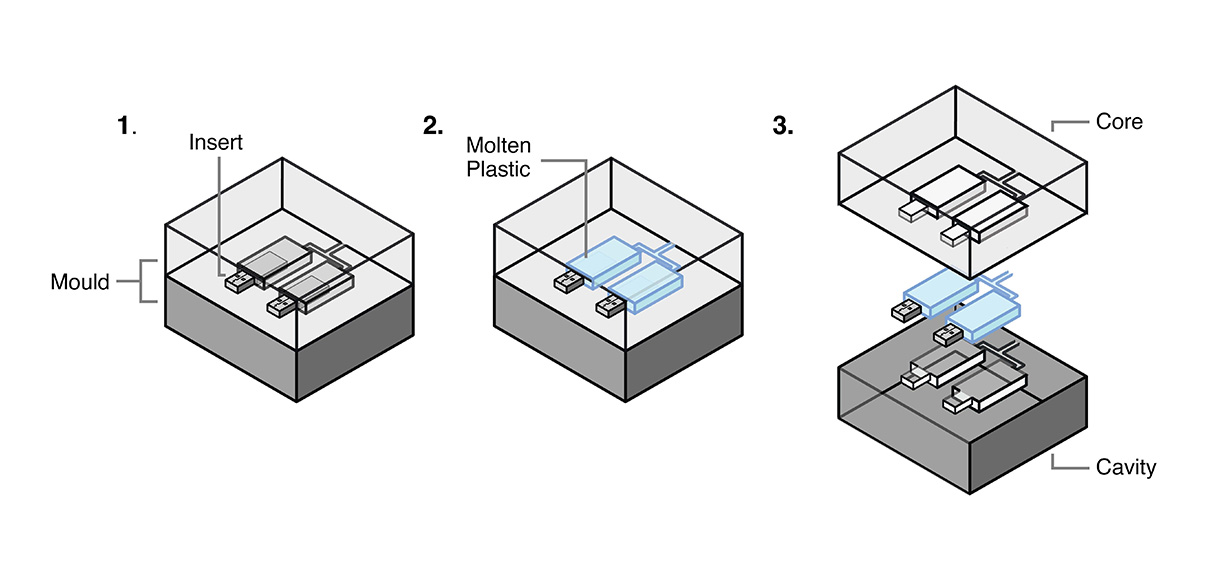

What is Insert Moulding?

Insert moulding is a subset of injection moulding techniques, similar to overmoulding, in which a ‘pre-formed’ component (known as an insert)—either machined or purchased off-the-shelf—is placed into the mould cavity before material injection. As the molten plastic is injected, it then surrounds and forms a strong bond with the insert during the moulding process, creating a single part.

- Materials Used in Insert Moulding: The insert can be made of metal, plastic or any other rigid materials, and the moulded material is usually a thermoplastic.

- Purpose of Insert Moulding: To enhance the functionality of a part by incorporating reinforcements, electrical conductivity, or specific features directly into the mould. It can result in greater strength, functionality and efficiency, as opposed to attaching the individual parts separately during post-production assembly operations.

- Insert Moulding Applications: Used to incorporate brass threaded inserts, fasteners, plastic clips, sensors, electronic components, and magnets into plastic parts; widely applied in the production of electronic components, automotive parts, and medical devices.

Advantages of insert moulding

- Improved Part Performance – By embedding electronics, sensors or threaded fasteners, insert moulding eliminates the need for screws and other fasteners, allowing for a less bulky design that can outperform alternative assembly methods. It can also protect sensitive components and enhance the strength or functionality of the final part.

- Fast Assembly Time – With manufacturing processes like CNC machining, sheet metal fabrication or 3D printing, any required assembly can be a major bottleneck, especially for larger volumes. Insert moulding can be used to eliminate the assembly stage, entirely in many cases.

- Significant Cost Reduction – While initial tooling costs for insert moulding may be higher, the process eliminates the need for post-production assembly. This makes the production of hundreds to thousands of pre-assembled parts per day possible, improving efficiency and reducing overall production costs at scale.

Disadvantages of insert moulding

- Design Complexity – While insert moulding may sound simple in theory, it can introduce several layers of complexity in practice. Designing a part that is compatible with a metal insert—or ensuring that delicate electronic components can withstand the high injection pressures and temperatures—involves careful consideration of material properties, thermal expansion and mould flow dynamics.

- Multiple Manufacturing Technologies – If the inserts are custom design and not off-the-shelf components, additional steps such as machining the metal parts or producing specially sized sensors or magnets may be required. This can increase the overall project time and cost.

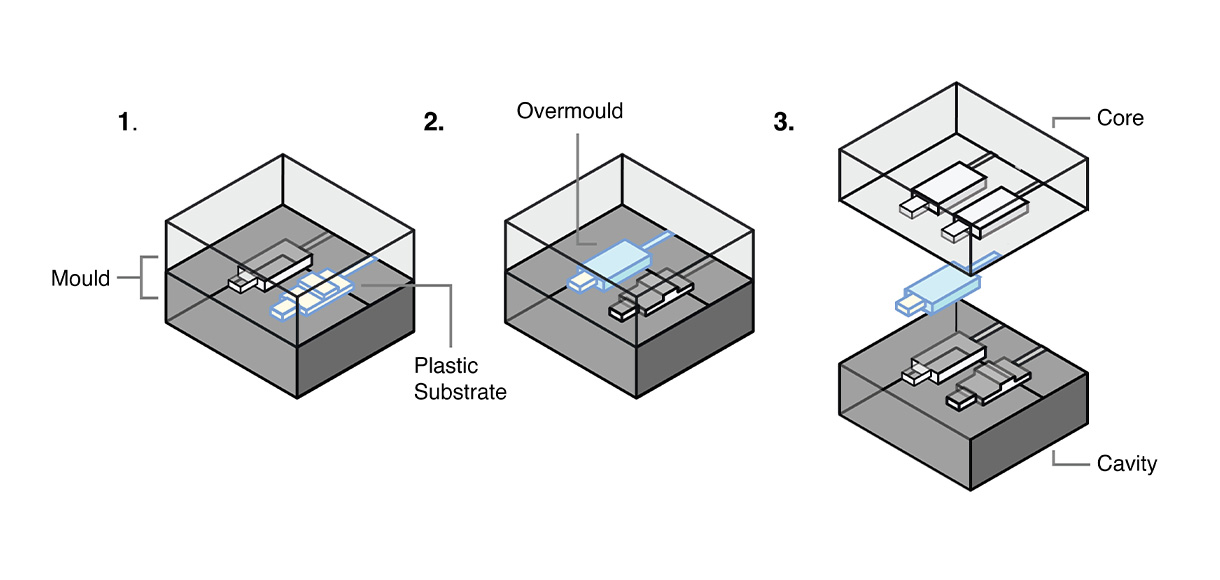

What is Overmoulding?

Overmoulding is another subset of injection moulding, a type of insert moulding, in which a base material (known as the substrate) is moulded first, and additional materials (known as the overmould) are then applied over specific areas or the entire part surface. Essentially, one plastic is moulded over another moulded part. During this process, the overmould forms a permanent bond with the substrate, resulting in a single part.

- Materials Used in Overmoulding: The base material is usually rigid, while the overmould material is softer or more flexible. Overmoulding often involves using different types or colours of thermoplastics, elastomers or rubber materials.

- Purpose of Overmoulding: To combine multiple materials or colours to enhance aesthetics, specific materials properties or achieve a robust and inseparable bond between two materials. This process can improve grip, durability, efficiency and overall part performance in a way that can’t be achieve through assembly.

- Overmoulding Applications: Used to enhance the grip, ergonomics, aesthetics, shock absorption or functionality of a product. It’s often seen in products like tool handles, toys, kitchen utensils, toothbrushes, and electronic device grips.

Advantages of overmoulding

- No Adhesives Required – Overmoulding allows different materials to be fused, eliminating the need for glues or other permanent bonding methods. This can help increase the overall durability and longevity of plastic parts.

- Increased Material Flexibility – Overmoulding allows engineers to combine multiple types of materials to improve vibration damping, produce soft seals, or create soft-grip features and textures in specific areas, which would be difficult or impossible to achieve with single-material parts. It also enables the straightforward production of multi-coloured components.

- Embedded Seals – Overmoulding offers the option of moulding soft seals into parts. An example would be an electronics enclosure that needs to be IP rated. Usually, the part will have a groove into which an o-ring can be installed later. However, it is far more cost-efficient and robust to permanently mould the seal as an integral component.

Disadvantages of overmoulding

- Multi-Production Processes – Overmoulding is a multi-step process that requires more complex tooling than single-material moulding and may even involve multiple tools or complex two-shot mould with increased upfront costs. Because multiple materials are used for each part, the unit cost also tends to be higher.

- Debonding – If the base and overmould materials are not compatible, or if the temperature is inconsistent or not properly optimized, delamination may occur after moulding . In such cases, complex mechanical interlocks or other bonding enhancements may be required to ensure a secure bond. In the worst case, the parts could fail entirely.

Should I Choose Insert Moulding Or Overmoulding?

Choosing between insert moulding and overmoulding depends on specific project needs, design requirements, material compatibility and the desired characteristics of the final product. To guide your decision, we’ve listed several scenarios in which it’s better to choose overmoulding over insert moulding and vice versa.

When to use insert moulding:

Consider insert moulding when making products that have the following attributes or applications:

- Your part has a metal component

- You need to efficiently integrate electronic components like sensors, wires or circuit boards.

- You need to incorporate other pre-fabricated substrate like magnets

- You want to avoid incurring the cost of a complex two-shot mould

- You must incorporate threaded inserts into your part.

When to use overmoulding:

Consider overmoulding when making products that have the following attributes or applications:

- Your finished piece can be made of thermoplastics and/or rubber.

- You intend to improve the grip and texture of a part.

- You need multi-colored plastic products.

- You want to increase cushioning, shock absorption or vibration damping.

- You need to embed soft seals into your part.