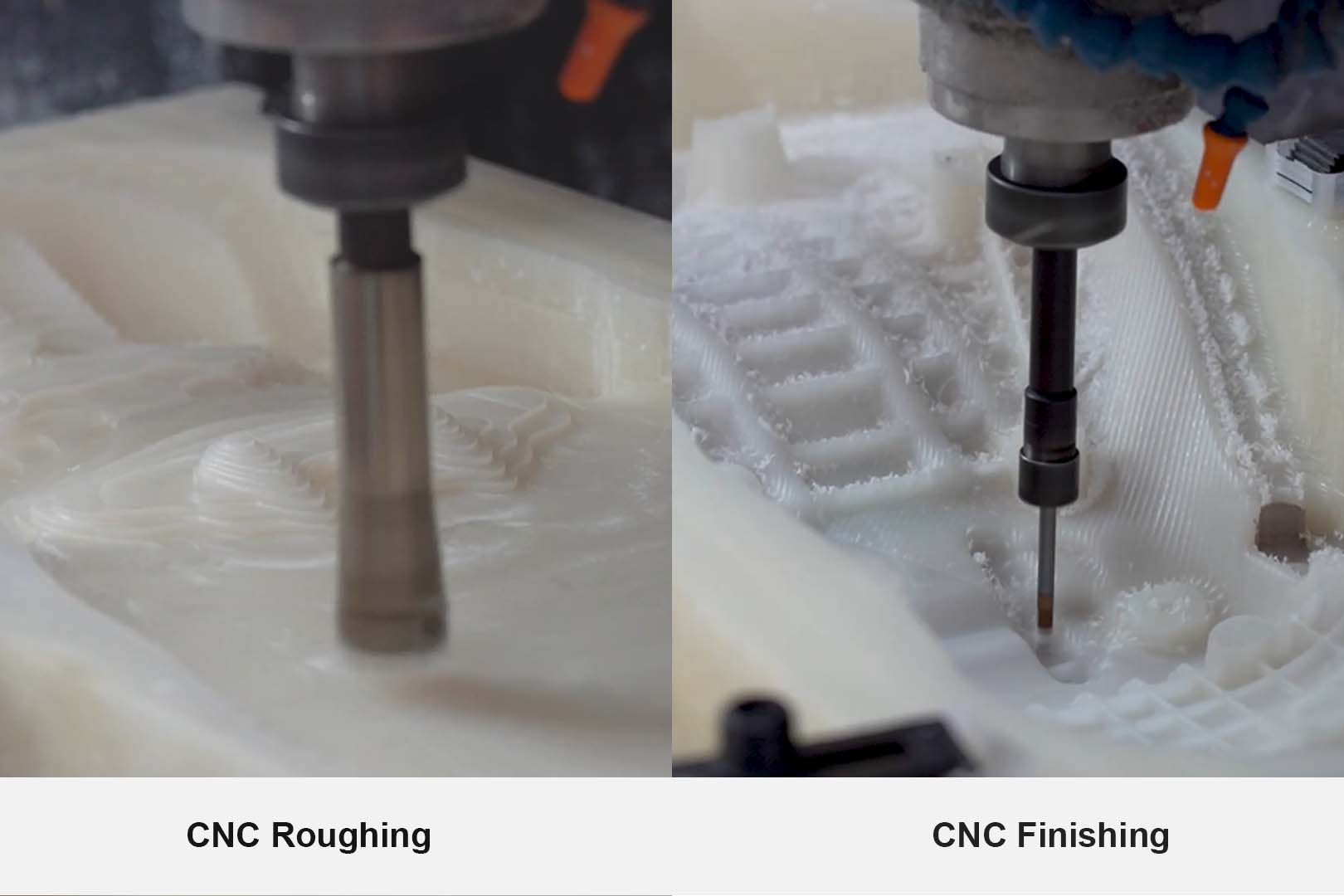

In CNC Machining, turning a solid block of raw material into a precise crafted component with good surface quality using a single machining operation is ineffective and often, impossible. As a result, manufacturers usually carry out two key production steps: roughing and finishing.

In this article, learn what roughing and finishing are, their advantages and uses, and how they compare in terms of objectives, material removal rates, costs and their effect on a part’s surface finish and dimensional accuracy.

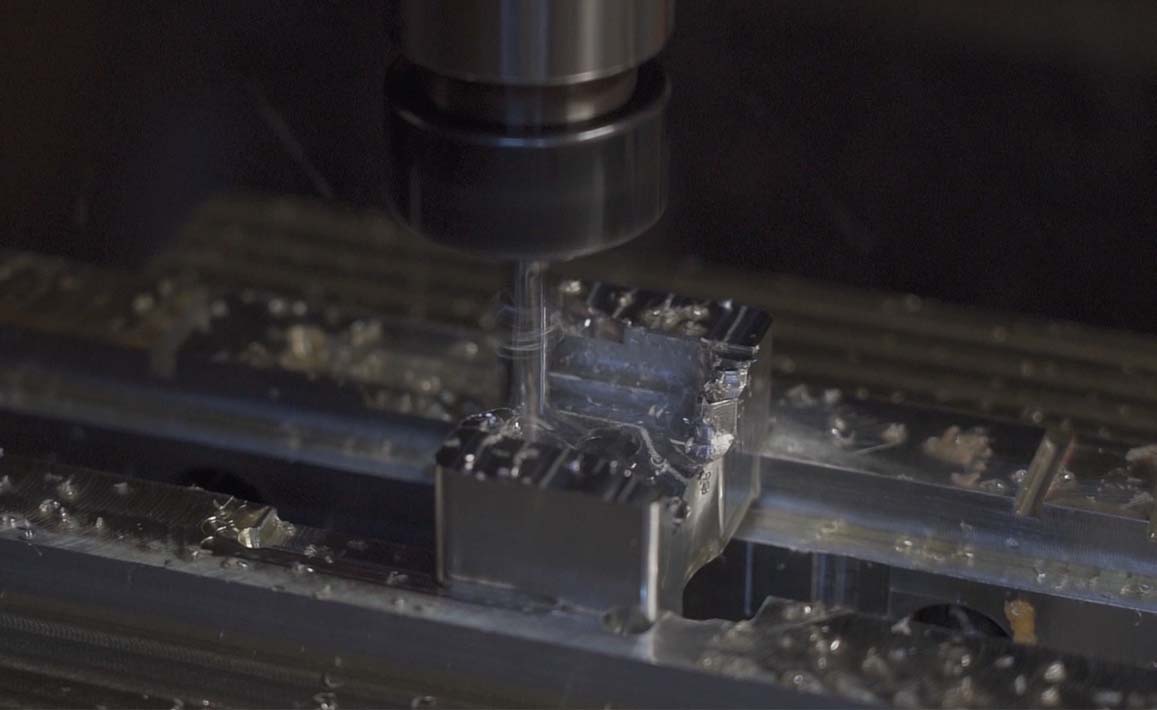

In the first step of machining, a bulk of excess material is removed from a workpiece taking into consideration the design requirements. High feed rate and depth of cut are employed for this step so that high stock removal rate is obtained. This step is called “rough machining” or “rough cut.”

Rough machining on its own cannot provide a good surface finish and high precision tolerances. After rough cutting, a “finishing” or “ CNC finishing” is carried out to improve dimensional accuracy, a higher feature tolerance and surface finish.

Finishing in machining refers to the process of altering the surface of a machined part for specific purposes—such as achieving tighter tolerances, enhancing aesthetics or mechanical properties, improving part performance, or extending its lifespan. Typically, finishing is performed in the final stage, after roughing operations.

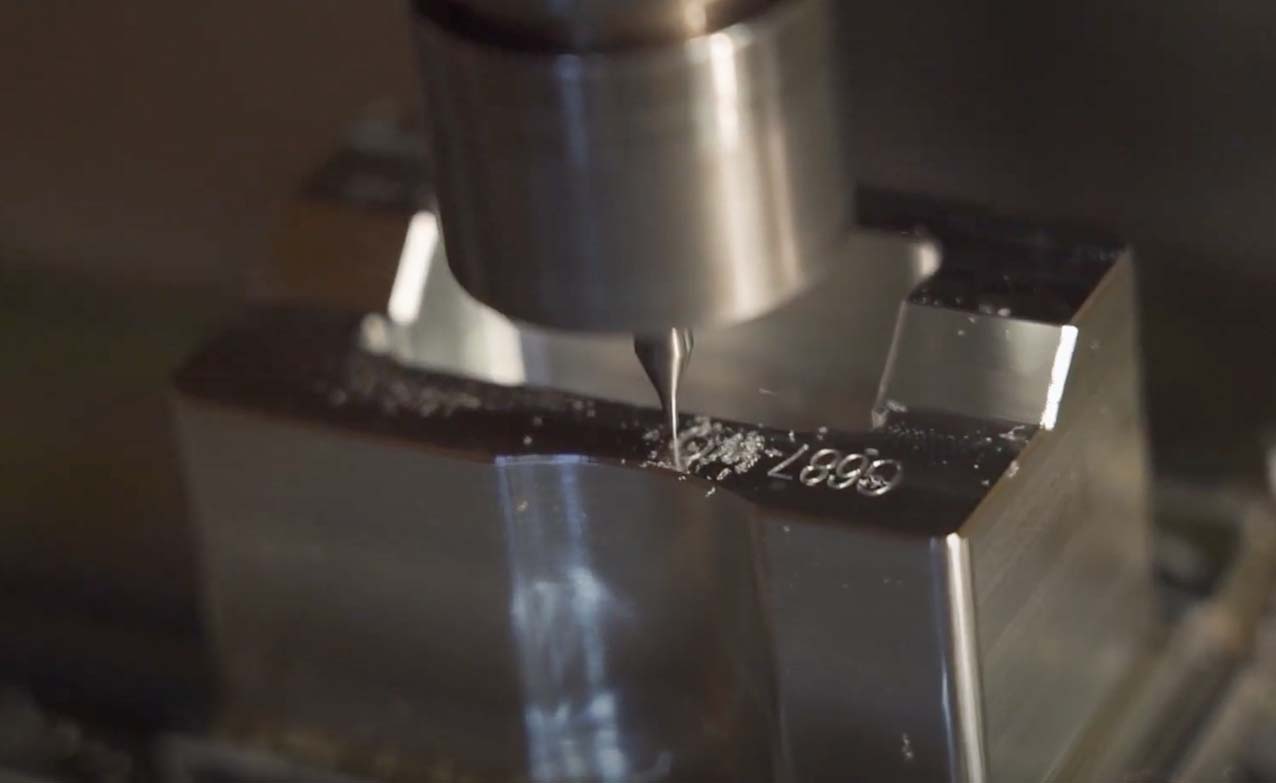

Some of the most common finishes include precision machining, texturing (specified using the “Ra” or “µm” value for average surface roughness), grinding, engraving, anodising, sandblasting, electroplating, painting, and other processes (check out more CNC finishes). Manufacturers may use a specific finishing process or a combination of finishes on different surface areas of a part. The choice of finish largely depends on the specific needs of your part.

Purpose

The purpose of rough machining is to remove as much excess material from a workpiece as quickly and efficiently as possible in the early stages in preparation for the final, more precise machining steps—like finishing—in shaping the part. On the other hand, finishing is focused on improving the part’s final dimensions, surface quality, and tolerances. It is the final stage of the machining process and is designed to refine the workpiece after rough machining.

Feed Rate and Depth of Cut

Roughing processes use higher feed rates and larger, deeper cuts for maximum material removal. In comparison, finishing processes use low feed rates and precise, shallow cuts to refine the part surface.

Material Removal Rate (MRR)

Roughing involves a high material removal rate while focusing on deep and wide cuts. In contrast, finishing operates at a much lower rate of material removal, focusing on lighter, more precise cuts to refine the workpiece. To give you a rough idea, the MRR for rough machining aluminium can range from 50 to 200 cubic inches per minute (CIPM), whereas finishing machining aluminium typically falls within the range of 1 to 15 CIPM.

Surface Finish

The higher feed rate and depth of cut employed in roughing produce more visible scallop marks or feed marks, resulting in a higher surface roughness and poor surface finishing. In contrast, the shallow cuts and small feed rates utilized in finishing operations leave fewer scallop marks, resulting in lower surface roughness and delivering high-quality surface finishes.

Dimensional Accuracy and Tolerance

Rough machining is designed for rapid material removal with less concern for precision. This is because finishing operations can more efficiently achieve better dimensional accuracy and tight tolerances by using finer cutting tools, lower feed rates, and additional processes.

Cutter Type / Tools

Finishing machining often requires sharp, expensive cutters that take a low chip load to achieve a refined finish. On the other hand, rough machining can utilize old tools and cutters with less sharp edges that take a high chip load since the quality surface finish is not a vital requirement.

Cost

Generally, finishing operations account for a larger proportion of total machining costs, while roughing operations are less expensive. This is because finishing requires more expensive cutting tools, longer machining times, and often additional processes like grinding and polishing.

| ROUGHING | FINISHING | |

| Objective |

|

|

| Machining Phase | Performed at the early machining stage, prior to finishing. | Performed at the later machining stage, after roughing. |

| Material Removal Rate (MRR) | Higher stock removal rate. | Lower stock removal rate. |

| Feed Rate and Depth of Cut | Higher feed rate. Larger, deeper cuts. | Very low feed rate. Precise, shallow cuts. |

| Surface Finish | Poor surface finish. | Good surface finish. |

| Dimensional Accuracy | Low dimensional accuracy, with less concern for tight tolerances. | High dimensional accuracy, with precise control over tight tolerances. |

| Cutter Type | Old cutters can be utilised for rough machining. | Sharp cutters are highly desired for better, more accurate results. |

| Cost | Generally accounts for less of the total machining costs. | Generally accounts for more of the total machining costs. |

Send your 3D CAD drawing to our Site Contact Form and tell us about your part material and finishing requirements. And our engineering team will get back with a Free Custom CNC Quote within 24 hours or less.