June 2025 – U.S. steel tariffs just doubled from 25% to 50% — and for injection moulders operating in the U.S., this changes the math on tooling for plastic injection moulding in a big way.

For years, Chinese-made steel moulds have been a competitive alternative to domestic tooling. Now, with the recent tariff increase on imported steel and aluminum, the case for sourcing moulds from China has grown even stronger. Here’s why:

With tariffs now at 50%, U.S. moldmakers face significantly higher raw material costs — expenses that are inevitably passed on directly to customers. The result: manufacturing in the U.S. just got more expensive, and fast.

Even before the tariff spike, Chinese-made steel tools were reported to be around 30% to 50% cheaper than Western alternatives. The new tariff regime amplifies that disparity, making offshore tooling an even more attractive option for companies focused on maximizing ROI.

Yes, you’ll still need to pay tariffs on imported plastic parts. But like many manufacturers, you can leave the mould in China, run production offshore, and import only the finished parts. For many, this approach still nets out as the cheaper option — especially at scale.

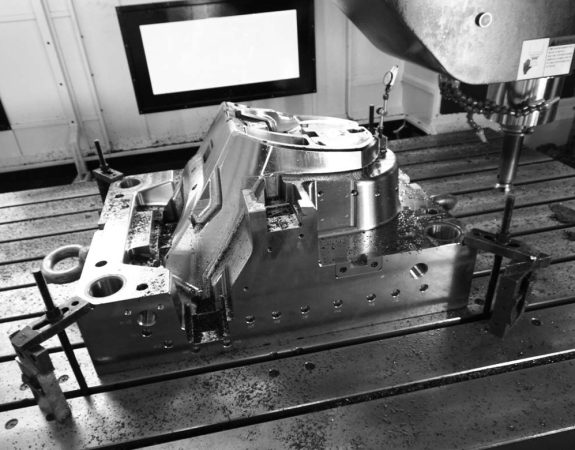

China is a major global hub for injection moulding, especially steel moulds — largely because they are affordable and readily available. The country’s deep expertise in steel tooling, combined with efficiency, reliability, and scale, continues to make China a compelling choice — especially in today’s shifting trade environment.

Multi-cavity tooling, insert moulding, overmoulding, 2-shot moulding, 2k moulding

Bottom Line: With U.S. steel tariffs now doubled, domestic tooling costs are climbing fast. For manufacturers navigating rising input prices and global competition, sourcing steel moulds from China isn’t just cost-effective — it may be the smartest strategic move in today’s global trade landscape. If you can get it done in China, it’s often your best ROI play.

At HLH, we make prototype tooling, bridge tooling and production tooling in-house for simple to complex injection moulding, overmoulding, 2k-moulding and insert moulding projects. Ready to start your project? Upload your CAD drawing to our site contact form, and our team will get back with a FREE quote within 48 hours or less.

Discuss your project with our team: info@hlhrapid.com