Sol is a tech company located in San Francisco, USA. They are the innovators behind the Sol Reader VR headset that is set to revolutionize the world of e-reading. What distinguishes Sol’s VR headset is that it isn’t looking to replace smartphones but is fully focused on one objective — to enhance users’ reading experience.

| Company | SOL |

|---|---|

| Location | San Francisco, USA |

| Industry | Consumer Technology |

| Product | Sol Reader, E-Ink VR Headset |

| Service | Vacuum Casting (rapid prototyping), Rapid Tooling & Injection Moulding, Silicone Overmoulding |

| Mould Material | P20 Mould Steel |

| Part Material | Nylon (PA) 610, TPSiV®Silicone |

| Surface Finish | Semi-Gloss SPI-B1, VDI-24, VDI-27, Polishing, Painting + Rubberized Paint |

| Quantity | 20+ individual components, First Run – 300 sets |

Keith Alsberg, Chief Mechanical Architect of Sol and expert product development engineer, has worked with HLH for over 20 years on a variety of projects including medical devices, industrial electronics and consumer products. Once again, Keith has returned to join forces with HLH, this time for the ground breaking development of Sol’s state-of-the-art E-reader VR technology, the Sol Reader.

When asked why he had chosen HLH as his choice manufacturer for the past 20 years, Keith responded, “because they’re very reliable, they have very good communication, good value for the different products they make, they’re fast, they’re easy to work with, and most importantly… they make beautiful parts. At the end of the day, that is what is the most important thing.”

This time, the requirements for Sol’s cutting edge VR technology project was no different. In preparation of their launch, the company needed a partner that could communicate with them effectively and meet their very aggressive prototyping and production schedule whilst fulfilling their quality standards.

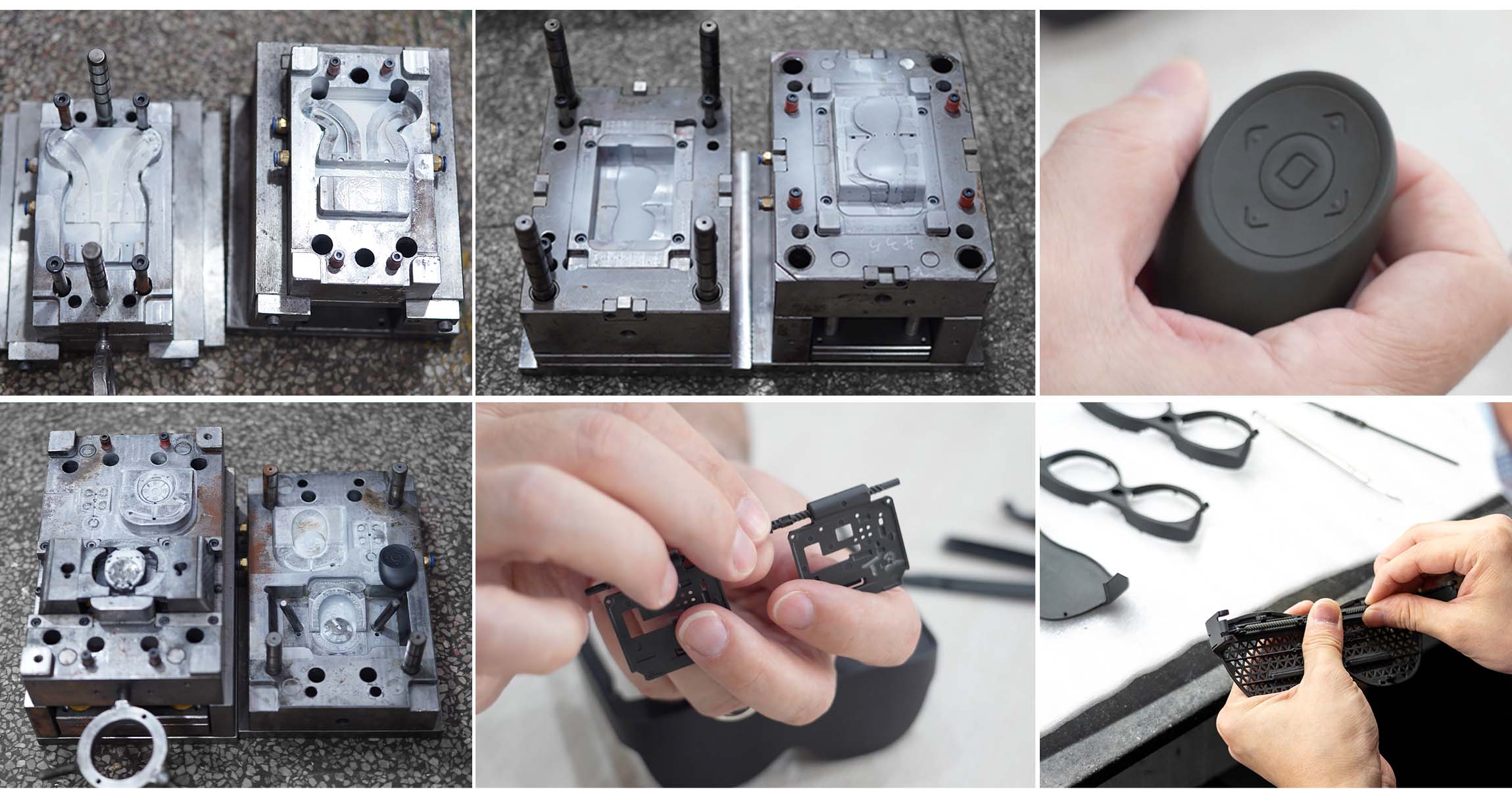

Resembling a pair of glasses, the Sol Reader is designed for convenience and comfort. But despite its simple and effortless external appearance, there’s more than meets the eye. The headset is made of many complex mechanical, optical, tight-fit assembly designs with silicone overmoulded components. “Some of these parts are very complicated — with side actions, shutoffs and pickouts — and HLH’s engineers have done a great job at figuring how to mould the parts,” said Keith.

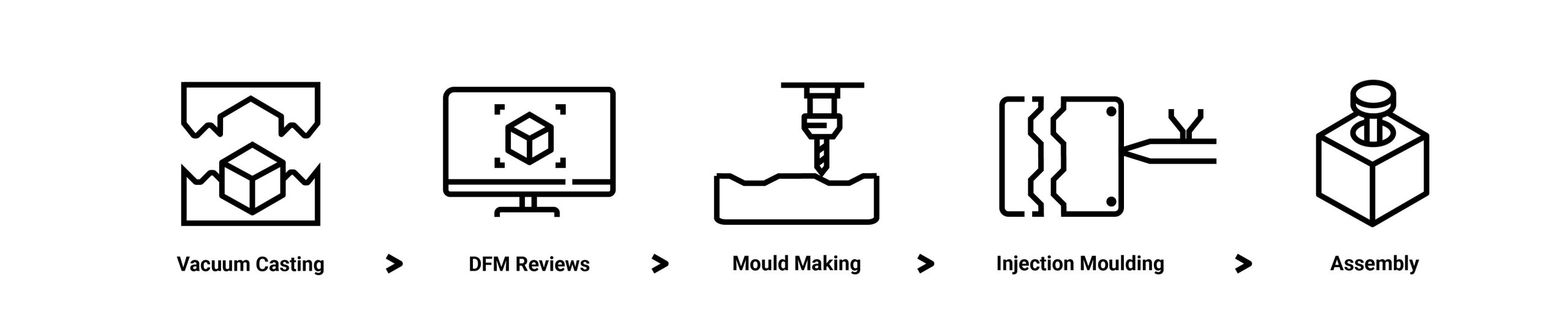

In partnering with HLH, Sol has effectively leveraged both our rapid prototyping and production services. In the early stages, HLH helped Sol rapid prototype their components via vacuum casting to achieve satin, matte, clear, frosted and several other high-quality finishes and textures on their prototypes. HLH then continued to support Sol by facilitating the tooling & injection moulding process for 20 over different components. This partnership has allowed Sol to seamlessly progress from prototyping to production and then to market, ensuring consistency within their development stages.

Sol has also benefited from HLH’s wide range of in-house machinery. Keith explained, “they have many different size injection moulding machines—from very large to small—the right size for whatever part we need to make.” He further shared, “It’s very exciting to see their growth! HLH, 20 years ago, was mostly a CNC company. Now they do CNC, rapid prototyping, injection moulding, painting, and finishing. It’s really a great company to work with.”

“HLH’s hard work and support made us get to a very aggressive schedule on time,” said Keith. “There are always challenges in any project, but HLH is a partner and we can work together to figure out the challenge whether it is a schedule or moulding challenge. It’s just a great experience working with them.”

Presently, Sol is preparing for the Sol Reader’s awaited launch. “We spent a lot of time doing the DFM of the part. A few minor things to fix but it’s amazing how we’ve had such good quality on the first trial,” said Keith. “The parts are great, we love it.” Having personally observed the meticulous thought-process and care invested into this project, HLH can’t wait to witness the final product in hand. Are you as excited for the Sol Reader as we are? You can join the waitlist here!

Looking to get your parts made with HLH? Get in touch with our team today through our submission form or at info@hlhrapid.com.