Get custom precision milled parts for rapid prototyping and production.

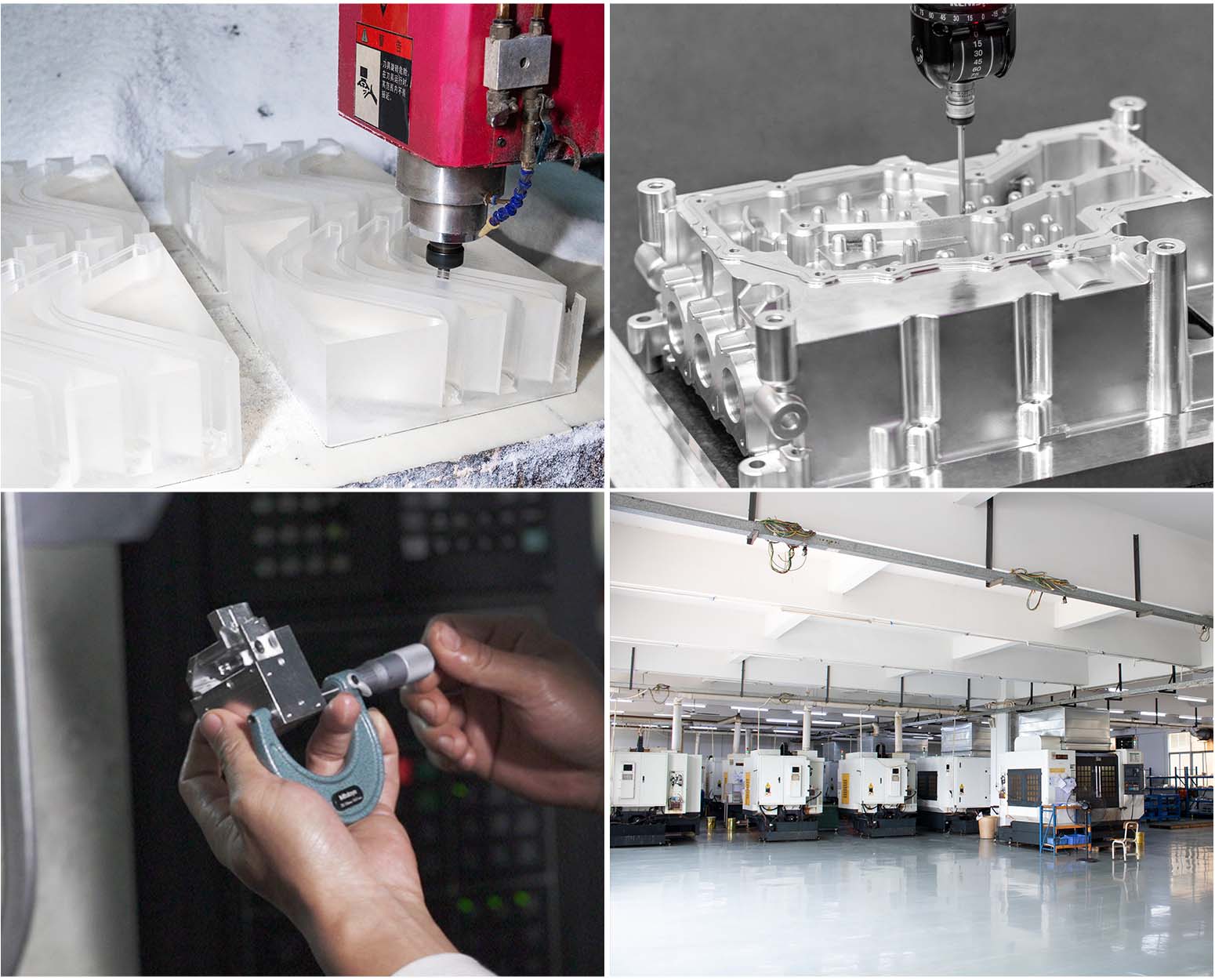

Through our 3, 4 and 5-axis milling services, we help industrial designers and engineers speed machine simple and complex precision engineered components at a competitive price. Our factory boast over 150 advanced CNC machines suitable for series production, CNC rapid prototyping, and one-off parts–if that’s all you need.

| Metals | Aluminium (2024, 6061, 6063, 6082, 7075, ADC12), Bronze, Brass, Copper, Stainless Steel (201, 301, 304, 316, 409), Steel (Galvanized, Hot Rolled, Cold Rolled, Alloys, Low Carbon, High Carbon, Tool Steel), Titanium Alloy, Magnesium Alloy, Zinc Alloy, etc. |

| Plastics | ABS, PMMA (Acrylic), POM (Acetel/Delrin), Anti-static POM, PC, PC+ABS,PA (Nylon), PPO, PA+GF, PP, PE, PPSU, PBT,PPS, PVC, Transparent PVC, EPP, Black PEEK, PTFE, PEI, Polyester, Bakelite, Silicone, etc. |

*more materials available on request

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

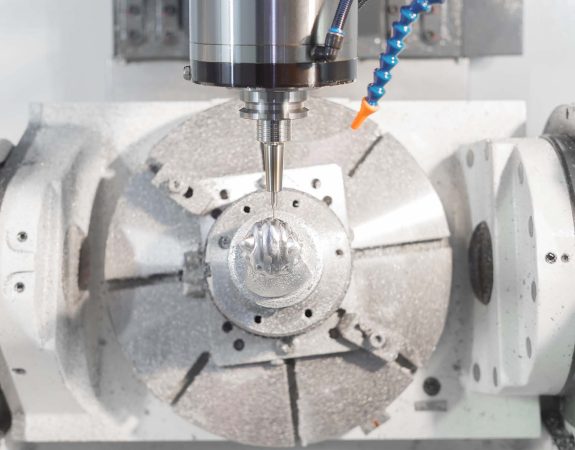

CNC milling, or Computer Numerical Control milling, is a subtractive manufacturing process that uses pre-programmed instructions and rotating cutting tools to remove material and shape a workpiece into a custom part. The two most commonly used milling machines in the industry are 3-axis machines, which are suited for simpler, basic shapes, and 5-axis machines, which are preferred for more complex geometries.

| Machine Type | Axes of Operation | Description | Key Aspects |

|---|---|---|---|

| 3-axis machining | X, Y, Z | Moves along three linear directions: left-right (X), front-back (Y), and up-down (Z). |

|

| 4-axis machining | X, Y, Z, A | Operates along three axes with added rotation along the A axis. |

|

| 5-axis machining | X, Y, Z, A, B | Can perform all 3-axis movements, with added rotation on A and B axes. |

|

CNC milling machines are particularly effective for creating complex 3D shapes with very tight tolerances. They minimize human error and are compatible with a broad range of materials—over 200 at HLH—including metals, hard plastics, and composites. This versatility makes them suitable for a wide range of applications, such as precision medical devices, lightweight aerospace and automotive components, and more. The only real limitation is with soft plastics that are too flexible to machine accurately.

Simple CNC mill parts may take several hours to machine, excluding setup and post-processing time.

More complex parts could take anywhere from several days to several weeks to produce.

At HLH, CNC milling projects are typically delivered in as little as 4 days, depending on the quantity and complexity.

In Europe, 3-axis milling jobs roughly cost between $30 to $40 per hour. For parts that demand high-speed 5-axis milling, costs can climb as high as $75 to $150 per hour. The price will vary significantly depending on the complexity and location of the job.

In China, as material, labour and setup costs are often much cheaper, 3-axis milling can start from $10 per hour. To better understand the costs of CNC, read the full article: How Much Does CNC Machining Cost?

Want to know how much your CNC mill project will cost? Try our online quote tool to get an instant estimate.

Simply put, the difference between turning and milling lies within the way the machine itself or the raw material moves. In CNC turning, the workpiece rotates against a cutting tool, whereas, in CNC milling, the material is held in place while the cutting tools rotate around it. CNC milling can be used in tandem with CNC turning to add design features, such as flat faces, that are impossible to achieve otherwise.