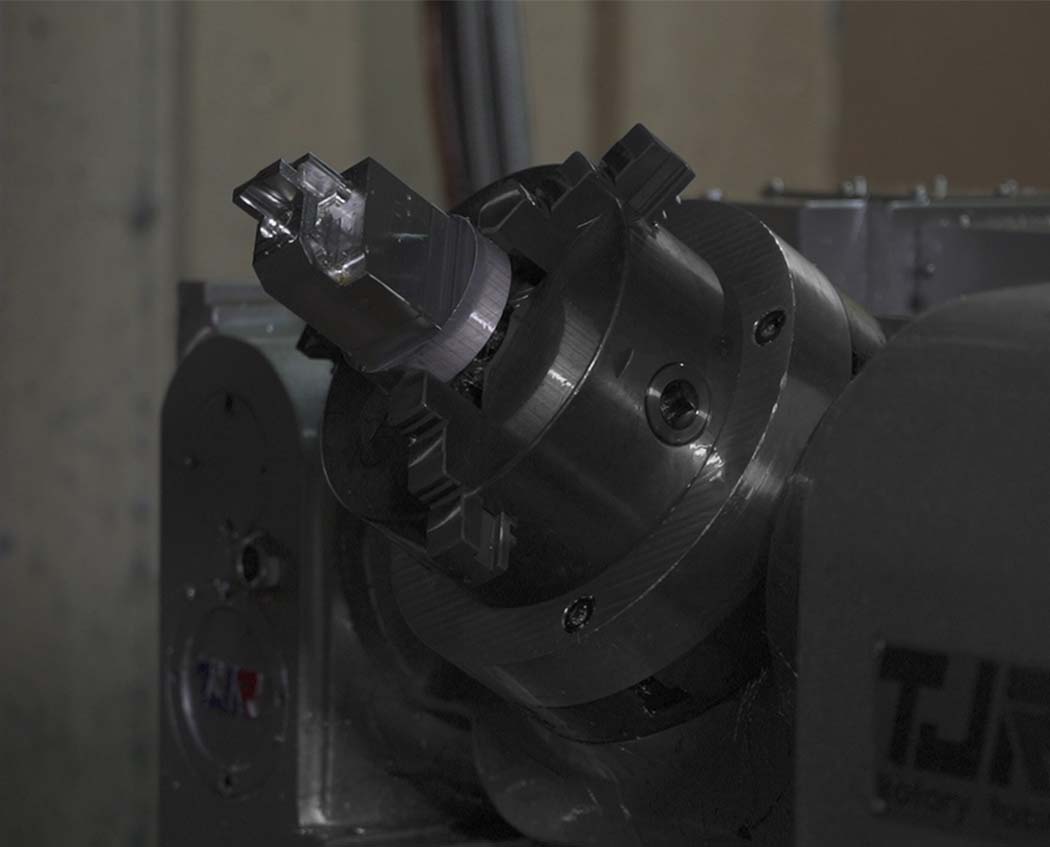

Get custom 5-axis machined parts for small batch and production runs.

5 Axis CNC Machining is our top choice for producing complex geometries and intricate shapes that would be challenging or impossible to achieve with 3- or 4- axis machining. Thanks to its precision and versatility, our 5-axis milling services have been used to create a variety of complex parts in various industries, such as: medical, aerospace, automotive, marine, bio-tech and more.

5-axis milling machines have opened the possibility for parts to be “Done in One,” reducing setup and cycle times as well as reorientation costs. The high throughput of these machines make 5-axis ideal for precision machining complex low-mix, high-volume production runs.

| Our capabilities | Description |

| Machine size | 3000 x 1200 x 850 mm |

| On-site machines | 100+ |

| Materials | 200+ metals, plastics, carbon fibre |

| Standard tolerance | ±0.05mm (metals), ±0.2mm (plastics) |

| Fast lead times | From 5 days |

| Metals | Aluminium (2024, 6061, 6063, 6082, 7075, ADC12), Bronze, Brass, Copper, Stainless Steel (201, 301, 304, 316, 409), Steel (Galvanized, Hot Rolled, Cold Rolled, Alloys, Low Carbon, High Carbon, Tool Steel), Titanium Alloy, Magnesium Alloy, Zinc Alloy, etc. |

| Plastics | ABS, PMMA (Acrylic), POM (Acetel/Delrin), Anti-static POM, PC, PC+ABS,PA (Nylon), PA+GF, PP, PE, PPO, PPSU, PBT, PPS, PVC, Transparent PVC, EPP, PEEK, PTFE, PEI, Polyester, Bakelite, Silicone, etc. |

| Composites | Carbon Fibre |

At HLH, our standard machining tolerance for prototypes and production runs is ISO-2678 Fine (F) for metals and Medium (M) for plastics, with tighter tolerances available upon request. Contact our team at info@hlhrapid.com for further information.

| Metals With Drawing | Metals No Drawing | Plastics With Drawing | Plastics No Drawing | |

| Linear Dimension | ±0.01mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

| Hole Diameters | ±0.008mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

| Shaft Diameters | ±0.004mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

5-axis machines are used to create highly complex geometries and intricate parts with high precision, which would be difficult or impossible to achieve with traditional 3-axis milling. At HLH, our 5-axis milling services have been used to create a variety of complex parts, including engine blocks, cylinder heads, gearboxes, and pumps.

5-axis machines are particularly useful for complex parts. However, if you only need a single part with less intricate geometries, 3- and 4-axis machining can often be a more cost-effective solution.

3-axis vs 5-axis CNC

5-axis CNC machining is an incredibly versatile subtractive manufacturing technique that operates simultaneously along five different axes (X, Y, Z, A, and B) to remove material from a solid workpiece, allowing for complex and intricate cuts in a single setup.

5-axis machining is one of the most advanced processes available today. Its advantages include high accuracy and reliability, fewer machine setups, increased efficiency, the ability to produce complex and intricate geometries, enhanced surface finishes, and improved drilling capabilities.

The cost of 5-axis CNC machining in the US and Europe can range from $75 to $150 per hour, or even higher in some cases. It can vary significantly depending on several factors including part complexity, quality of the machine, skill of the operator and the specific industry.

5-axis milling services are typically more affordable in China due to lower labour costs for skilled machinists. For less complex parts or bulk production, rates starting around $30 per hour are not uncommon, but again, the cost can vary depending on factors such as the quality of the service, part complexity, and the location of the machining service within China.