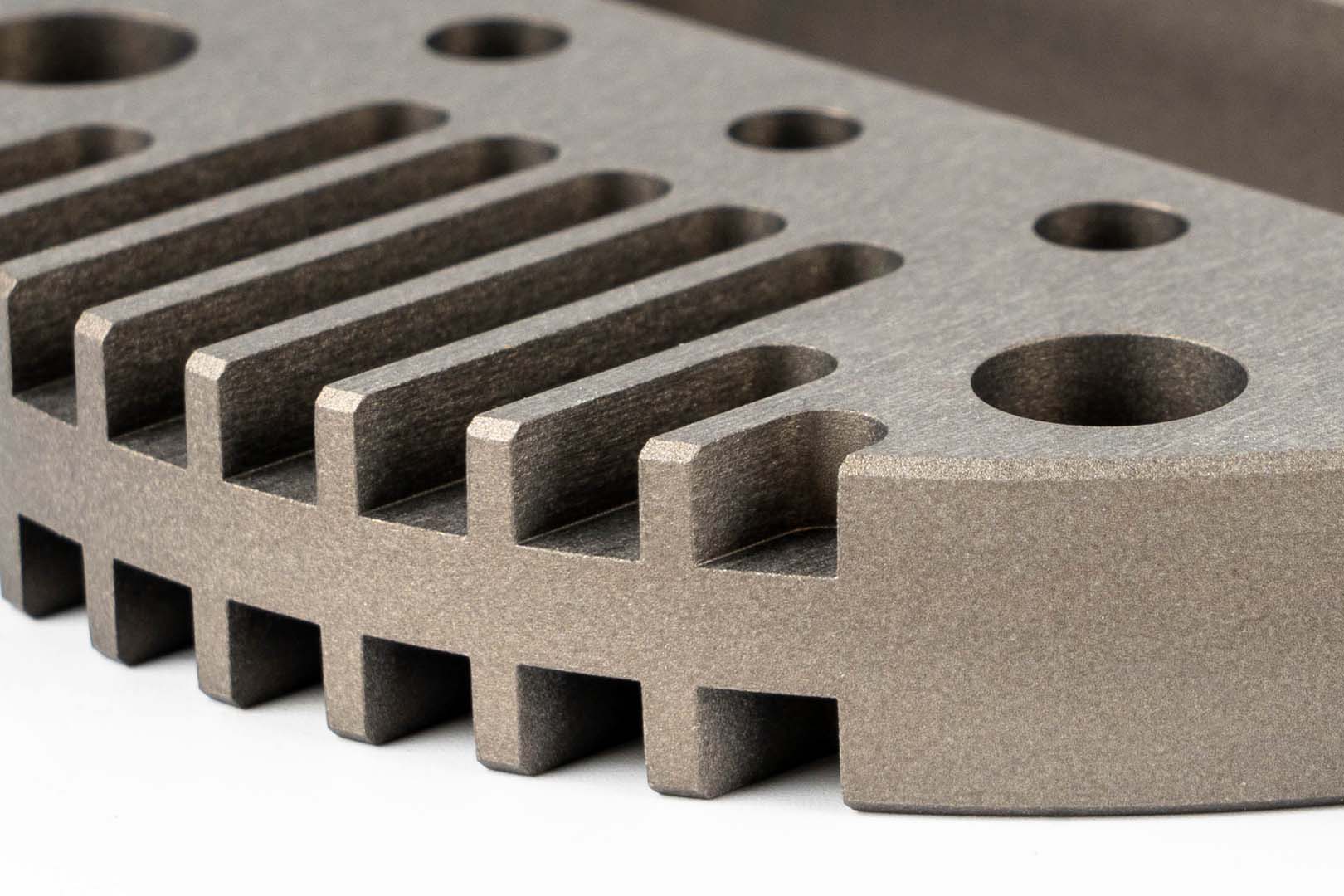

We offer high quality anodizing services for cnc machined aluminium and other metal parts

| Applicable to | Glossiness | Coating Thickness | Appearance |

| Aluminium, Titanium | Glossy, matte | 50µm to 150µm | Gold, red, blue, black, green, clear, etc. |

We offer clear anodizing services that produces a translucent oxide layer that allows some of the underlying metal material to show through. It’s often used for engineering components, kitchen utensils and other parts where a natural look is desired.

We offer colour anodising services by colour dipping or electrolytic colouring. This type of anodizing is often used on external automotive parts, enclosures and other products where a decorative finish is desired.

Anodizing vs Alodine

Anodizing will result in a non-electrically conductive aluminium whereas alodine will help preserve conductivity of aluminium parts. Anodizing is also a more durable finish that can withstand more wear and tear than an Alodine finish.

Main advantages of anodizing

Anodising is an electrochemical process that converts a metal surface into a decorative, anodic oxide finish. The process can be divided into five basic parts: preparing the surface, anodizing itself, cleaning the parts, adding colour and sealing the pores.

The main purpose of anodizing is to improve properties such as wear resistance, corrosion resistance, durability aesthetics, heat dissipation, dielectric (non-conductive) properties and adhesion of Aluminium and other metal parts.

The main disadvantages of anodizing include:

We offer high quality anodizing services for cnc machined aluminium and other metal parts