At HLH, we can work with 80+ materials for your custom CNC project. Explore them below!

| Strength | Corrosion | Typical Tolerances | Features | *Click image to enlarge | |

|---|---|---|---|---|---|

| AL6061 | Medium | Good | ISO 2768 fine | – Most widely available aluminium grade in China – Good machinability and corrosion resistance – Excellent for hard anodising * Lower strength compared to AL7075 and AL2024 |  |

| AL6061-T6 | Good | Good | ISO 2768 fine | – High strength and hardness for structural CNC parts – Good corrosion resistance * Lower strength than AL7075-T6 |  |

| AL7075 | Very High | Moderate | ISO 2768 fine | – Excellent strength-to-weight ratio – Hardness comparable to steels – Good fatigue resistance * Higher in price |  |

| AL7075-T6 | Excellent | Moderate | ISO 2768 fine | – Heat-treated (T6) with peak strength and hardness – Excellent fatigue resistance * Lower corrosion resistance (requires protective coating), higher cost |  |

| AL6082 | Good (medium-high) | Excellent | ISO 2768 fine | – Medium-strength alloy – Good formability and corrosion resistance * Not ideal for thin-wall structures |  |

| AL6082-T6 | Very High | Excellent | ISO 2768 fine | – Strong structural alloy – Excellent corrosion resistance – Good machinability * Lower strength than AL7075 and AL2024 |  |

| AL6083 | Good (medium-high) | Excellent | ISO 2768 fine | – Medium-strength alloy – Similar to AL6082 * Less widely available than AL6082 in Europe |  |

| AL6063-T6 | Medium | Excellent | ISO 2768 fine | – Medium-strength alloy – Good corrosion resistance and excellent surface finish – Ideal for architectural and industrial applications * Not ideal for heavy structural use |  |

| AL5083 | Medium | Excellent | ISO 2768 fine | – Medium-strength alloy – Excellent corrosion resistance and great weldability and formability – Ideal for marine applications * Not ideal for high temperature applications (>100 °C) |  |

| AL2014-T6 | Very good | Poor | ISO 2768 fine | – Very high strength and hardness – Good machinability and excellent strength-to-weight ratio – Suitable for high-load applications * Less ductile compared to other aluminium alloys |  |

| Strength | Corrosion | Typical Tolerances | Features | *Click image to enlarge | |

|---|---|---|---|---|---|

| SS316 | Excellent | Very Good | ISO 2768 fine | – Good tensile strength and toughness – Higher corrosion and chemical resistance than SS304 – Ideal for marine applications * More expensive than SS304 |  |

| SS316L | Very Good | Very Good | ISO 2768 fine | – Excellent corrosion resistance – Good strength and toughness – Superior for welded applications * Slightly lower tensile strength compared to SS316 |  |

| SS304 | Good | Good | ISO 2768 fine | – Cost effective steel material – Excellent corrosion resistance – Good mechanical properties * Susceptible to scratches * Lower corrosion resistance in chloride environments |  |

| SS303 | Moderate | Good (lower than SS304) | ISO 2768 fine | – Excellent toughness and machinability – 15-20% faster to machine than SS304 – Ideal for higher volume CNC production * Lower corrosion resistance than SS304 and SS316 |  |

| SS321 | Moderate | Good (similar to SS303) | ISO 2768 fine | – Excellent high-temperature oxidation resistance (titanium-stabilized) – Good toughness and mechanical strength – Good corrosion resistance * Machinability lower than SS303 (slower to cut) * More expensive than SS304 |  |

| SS416 | Moderate | Moderate | ISO 2768 fine | – Magnetic – Can be hardened for strength gain through aging or heat treatment – Good weldability and formability * Lower toughness than other stainless steel grades |  |

| SS440C | Very Good (after treatment) | Moderate | ISO 2768 fine | – One of the hardest and strongest stainless steel grades – One of the most wear-resistant stainless steel grades – Ideal for knives, bearings and precision parts * More expensive than basic stainless steels like 304 and 316 |  |

| SS17-4PH | Very Good (after treatment) | Moderate | ISO 2768 fine | – One of the strongest stainless steel grades – Higher tensile strength than SS440C – Good wear resistance after heat treatment (lower than 440C) * More expensive than basic stainless steels like 304 and 316 |  |

| Appearance | Mechanical Performance | Typical Tolerances | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

| ABS | Cream-yellowish ABS | Moderate stiffness; High toughness; Moderate friction | ISO 2768-1 medium | – Excellent mechanical properties – High impact strength – Good insulating properties * Low heat resistance * Prone to markings (especially Black ABS) |  |

| White ABS |  | ||||

| Black ABS |  |

| Appearance | Mechanical Performance | Typical Tolerances | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

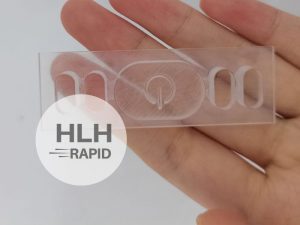

| PMMA | Deburr | High stiffness; Low toughness; Moderate friction | ISO 2768‑1 medium | – Higher clarity – More scratch-resistant – Easier to machine polish than PC material * Lower heat resistance and more prone to cracking and chipping |  |

| Polished — High Transparency |  |

| Appearance | Mechanical Performance | Toughness / Impact | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

| PEEK | Beige, Light Brown | Very high stiffness; Excellent toughness; Low friction | ISO 2768‑1 medium | – High-performance thermoplastic with exceptional strength – High-temperature resistance (up to 260°C) – Excellent chemical and wear resistance * High-cost CNC plastic material * Difficult to machine due to heat buildup and susceptible to internal stress |  |

| PEI | Ultem® (Translucent-amber coloured) | High stiffness; Good toughness; Moderate friction | ISO 2768‑1 medium | – High strength and rigidity – Exceptional thermal stability and good chemical resistance – Slightly lower cost alternative to PEEK * High-cost CNC plastic * Can be more brittle |  |

| PPS-GF40 | Black | Very high stiffness; Moderate toughness; Moderate friction | ISO 2768‑1 medium | – Higher stiffness than PEEK – Excellent dimensional stability under load – Excellent chemical and thermal resistance * Higher cost CNC plastic * More brittle due to glass-filled additives |  |

| PPSU | Radel® PPSU (Translucent-amber coloured), Medical Grade | Good stiffness; Excellent toughness; Moderate friction | ISO 2768‑1 medium | – Excellent impact and fracture resistance – High thermal resistance and good chemical resistance – Medical Grade CNC plastic * High-cost material * Lower stiffness compared to PEEK or PPS-GF40 |  |

| Appearance | Mechanical Performance | Typical Tolerances | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

| PC | High Transparency (slight blue-grey tint) | Excellent stiffness; Excellent toughness; Moderate friction | ISO 2768‑1 medium | – More durable, heat resistant and impact proof than PMMA – Exceptional mechanical, thermal and electrical properties * Scratches more easily and generally more difficult to process * Slightly less transparent PMMA and more expensive than PMMA |  |

| Translucent and Solid (opaque) |  |

| Appearance | Mechanical Performance | Typical Tolerances | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

| HDPE | HDPE Black | Low stiffness; High toughness; Low friction | ISO 2768‑1 medium | – Low cost CNC plastic – Excellent chemical and moisture resistance – Easy to mill, turn and drill * Dimensional instability and low wear resistance * Challenging to achieve smooth finish |  |

| Appearance | Mechanical Performance | Typical Tolerances | Pros and Cons | *Click image to enlarge | |

|---|---|---|---|---|---|

| POM | POM Black | Good stiffness; Moderate toughness; Low friction | ISO 2768‑1 medium | – Strong resistance to repeated impacts – Good electrical properties – Excellent dimensional stability * Easily deforms when machined due to heat buildup * Limited UV resistance and moderate chemical resistance |  |

| POM White |  |

At HLH, we can work with 80+ materials for your custom CNC project. Explore them below!