Use carbon fibre where less weight equals better performance.

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

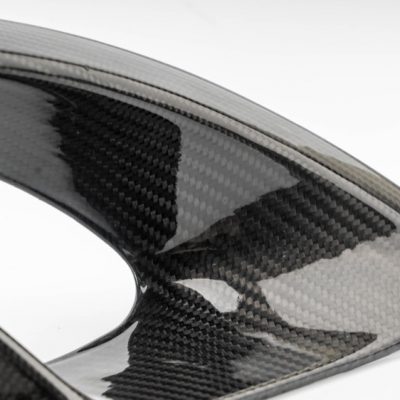

Carbon fibre parts are revolutionizing many industries and their weight saving advantages are being used extensively where less weight equals better performance. HLH manufacture tooling and carbon fibre parts for UAV, automotive and sports products among others. We have in-depth experience manufacturing composite parts to very high quality and repeatability.

Much of the process is still manual. A mould tool is manufactured often from aluminium or steel depending on the quantity of parts required and the tolerances required. The carbon fibre prepreg sheets are then manually laid by our skilled technicians. Following this the parts are then cured. Post processing options are wide and varied.

Carbon Fibre vs Glass Fibre

Carbon fibre is more than 20 percent stronger than the best fibreglass. It boasts a strength to weight ratio approximately twice that of fibreglass.

Carbon Fibre is Used For

Automotive parts, aerospace components, and various other applications where light weight but high strength parts are required, replacing sheet metal parts.

Advantages of Carbon Fibre

Carbon Fibre is a polymer and is sometimes known as graphite fibre. It is a strong, stiff, lightweight material that has the potential to replace steel and is popularly used in specialized, high-performance products like aircrafts, race cars and sporting equipment.

The main difference is that Kevlar essentially contains nitrogen atoms and carbon fibre mainly contains carbon atoms. Kevlar has a better abrasive strength than carbon fibre, whilst carbon fibre has the best strength and rigidity to weight ratio in the industry.