High precision, low cost metal part

production services with HLH

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

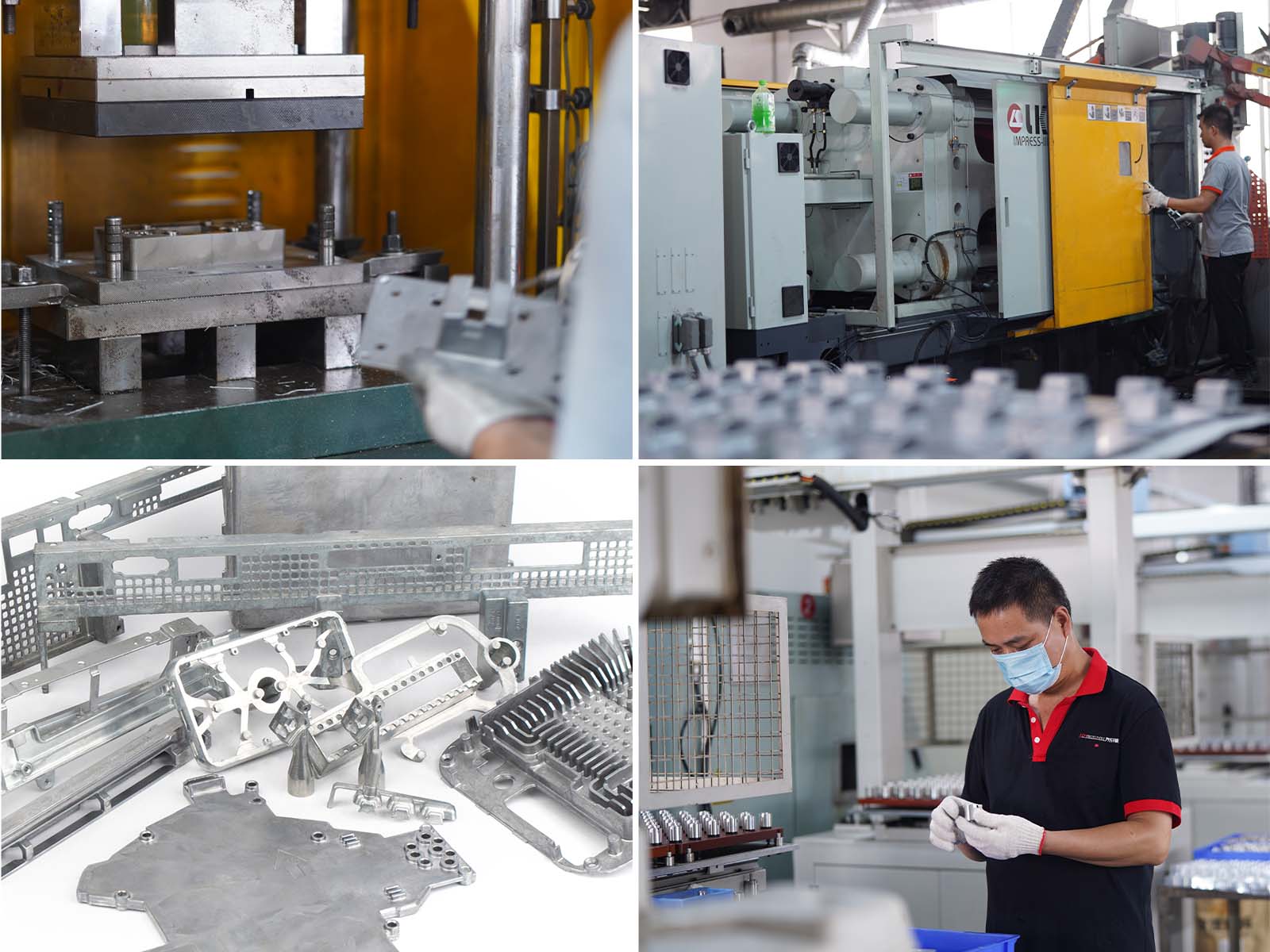

HLH offers pressure die casting services, ideal for manufacturing higher volumes of metal parts in aluminium, zinc, or magnesium. We manufacture high quality die cast tools, offer precision die casting and post process machining and finishing options. When it comes to producing high volumes of complex metal parts, die casting is our top choice.

| Our Capabilities | Description |

| Machine size | 80 – 800 ton |

| Material | Aluminium, Magnesium, Zinc Alloy |

| Mould life | 10,000 to 1M+ shots |

| Mould type | single cavity, multi cavity and family mould |

| Lead time | T1 samples as fast as 3 weeks |

| Material | Reference | Description |

|---|---|---|

| Aluminium Die Casting | A380, 383, A413, A360, CC401 | Aluminium die cast alloys are lightweight and can withstand some of the highest operating temperatures. Its great strength-to-weight ratios, make it popular for automotive components and aerospace applications. |

| Magnesium Die Casting | AZ91D, AM50A, AM20, AM60B | Magnesium die cast alloys are strong, rigid materials that have good corrosion resistance. They are typically used for electronic products. |

| Zinc Die Casting | Zamak 3, Zamak, 2, Zamak 5 | Zinc die cast alloys are typically lower in cost compared to aluminium and magnesium. They offer good stability and have excellent electrical and thermal conductivity, making them popular for under-the-hood parts and electrical applications. |

A mould tool is first manufactured by HLH’s highly skilled toolmakers and engineers. It is then installed on a die casting press and molten metal is injected under high pressure into the tool cavity. The parts can then be finished in a range of ways including powder coating and anodizing.

We offer a variety of die cast surface finishing and post processing options to achieve high-quality textured and aesthetic finishes for your product.

| Zinc Alloy | Aluminium Alloy | Magnesium Alloy | Copper Alloy | |

|---|---|---|---|---|

| Basic Tolerance up to 1″ (25.4mm) | ±0.010 (±0.25mm) | ±0.010 (±0.25mm) | ±0.010 (±0.25mm) | ±0.014 (±0.36mm) |

| Additional Tolerance for each addition inch over 1″ (25.4mm) | ±0.001 (±0.025mm) | ±0.001 (±0.025mm) | ±0.001 (±0.025mm) | ±0.003 (±0.076mm) |

Die Casting vs Metal Injection Moulding

Metal injection moulding, or MIM, is intricate and requires several steps to create parts. It is well suited for small intricate parts and large volume manufacturing. In comparison, die casting, has fewer steps and is economically feasible for smaller and larger runs when compared with MIM. It is used for creating larger geometrically complex components.

Die Casting is Used For

Producing (up to 100,000+) complex-shaped, industrial grade metal parts from real materials. Die casting is commonly used for making automotive components and decorative hardware.

Advantages of Die Casting

Die cast parts are made in steel moulds, similar to those used in injection moulding, but use low melting point metals such as aluminum and zinc instead of plastics. More metal parts are made by die casting than by any other casting process.

To create the die cast part, molten metal is forced into a mould via high hydraulic or pneumatic pressure. These steel moulds, or dies, produce extremely complex, high tolerance parts in a repeatable process.

Also known as gooseneck casting, hot chamber is the most popular die casting process. A chamber of the injection mechanism is immersed in molten metal and a “gooseneck” metal feed system brings the metal into the die cavity.

Sometimes it makes sense to bring production back closer to home and when it does, HLH is on hand to support with our export metal mould tooling service.

Due to its versatility, reliability and accuracy, die casting is widely used for many applications across different industrial sectors, including the automotive, medical, and electronics industries.