Medical device prototyping is key to building a successful medical product. At HLH, we have been working with global medical device manufacturers as well as startups to deliver high-quality precision parts and rapid prototypes within a minimum lead time. Our rapid tooling and injection molding services also offer the perfect solution for low/mid volume production from a wide range of medical grade materials.

✓ FDA Class 1 and 2 devices

✓ Surgical and sanitation robots

✓ Surgical tools, anatomical models, simulation/training prototypes

✓ Medical housings & enclosures and prosthetic devices

✓ Wellness devices and wearables

| Technologies | Top Materials | Top Surface Finishes | Description |

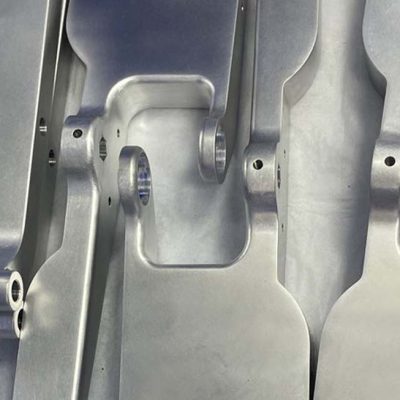

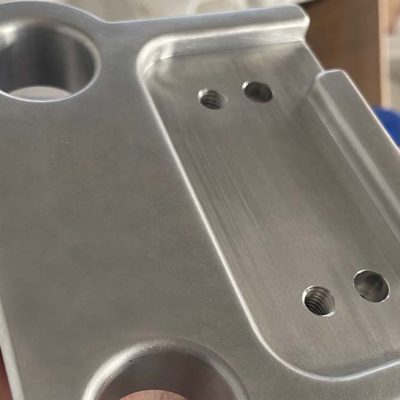

| CNC machining | Aluminum, stainless steel, PC, PEEK, Acrylic, etc. | Anodizing, passivation, electroplating, silk screening and more. View Full List | Precision prototypes for functional testing and validation of appearance, and biocompatible parts for patient end-use applications. |

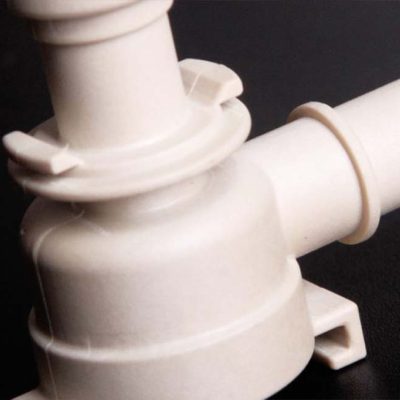

| Plastic injection moulding | POM, PEEK, PA+GF, etc. | SPI surface finish, pad printing, painting and more. | Rapid tooling, insert moulding, overmoulding, and two-shot and 2K moulding services for simple and complex low volume parts. |

| 3D printing | Nylon, PLA, ABS, TPU, etc. | Electropainting, metallic oil paint, polishing and more. | Functional prototypes and custom end-use parts via SLS, MJF, and DMLS. High resolution and anatomically accurate models via SLA and MJP. |

| Vacuum casting | Soft rubber, ABS-like, PC-like, etc. | Gloss, semi-gloss, matte. | Ideal for rapid prototyping and manufacturing a small batch of end-use devices from a variety of textures, stiffness, strength, hardness and softness. |

| Sheet metal fabrication | Aluminium, stainless steel, cold rolled steel, etc. | Anodizing, brushing, passivation and more. | Reliable solution for prototyping thin sheets of brackets, frames, housings and enclosures with tight tolerances and precise dimensions. |

U.S. medical equipment company, R2R MedEquip, orders over $30k worth of prototypes and leaves a review about HLH Rapid’s services, lead time, shipping, and part quality.

HLH Rapid’s director James Murphy sits down with Alistair Williamson, a veteran of medical device development with 30+ years of experience in product design, to talk designing successful medtech devices and more.