Considering ABS injection moulding for your next plastic project? Learn about the properties of ABS material, its pros and cons, as well as common applications and alternative material options.

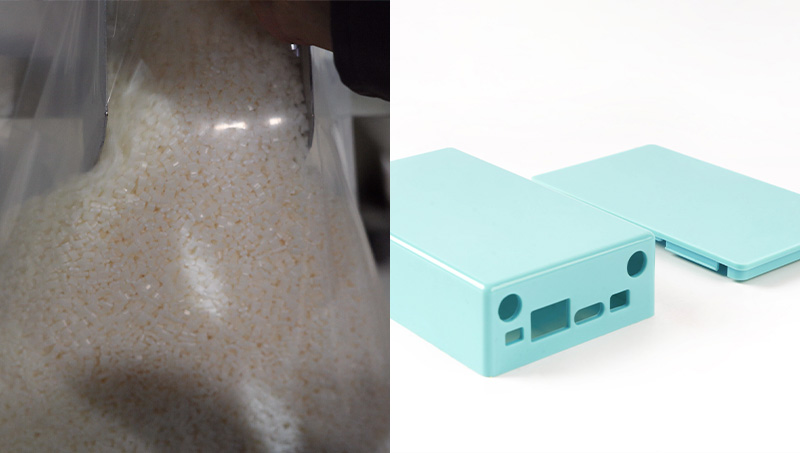

Acrylonitrile Butadiene Styrene (ABS) is one of the most common plastic material available and often regarded as a “safe” thermoplastic polymer for injection moulding. This is because ABS resin is non-toxic, durable, has high impact resistance and good chemical resistance, relatively low cost, and compatible with many surface finishes including chrome plating.

Overall, ABS is a very versatile material.

| Polylac® (PA-765) | Cycolac™ (MG47) | Lustran® (348) | RTP (605) 30% GF | |

|---|---|---|---|---|

| Density (g/cm3) | 1.19 | 1.04 | 1.06 | 1.27 |

| Shrinkage Rate (%) | 0.3–0.6 | 0.5–0.8 | 0.4–0.6 | 0.1–0.2 |

| Rockwell Hardness (R) | 100 | 112 | 112 | – |

| Tensile Strength at Yield (MPa) | 39 | 44 | 48.3 | 96.5 |

| Elongation (%) | 10 (Break) | 24 (Yield) | – | 1–2 (Yield) |

| Flexural Modulus (GPa) | 1.80 | 2.30 | 2.69 | 8.27 |

| Flexural Strength (MPa) | 55 | 70 | 75.8 | 134 |

| Drying Temperature (°C) | 87.8–93.3 | 80–95 | 79 | 82.2 |

| Drying Time (hrs) | 2–24 | 2–4 | 2–4 | 2 |

| Melt Temperature (°C) | 232–249 | 220–260 | 246–274 | 204–238 |

| Mold Temperature (°C) | 54.4–71.1 | 50–70 | 29–60 | 62.8–85 |

*Material properties of common ABS grade

For added strength, filler materials such as glass, nylon, acrylic, and stainless steel fibers can be added. Additives affect processing parameters, however, and different grades of ABS may contain different combinations of acrylonitrile, butadiene, and styrene

From vacuum cleaners to kitchen appliances, ABS is a versatile material with a wide range of applications across the medical, automotive, robotics and many other industries. Some common applications include:

When higher heat resistance, toughness and impact resistance are needed, Polycarbonate (PC) is a good alternative to ABS. PC is a high-performance, engineering thermoplastic known for its exceptional toughness, dimensional stability, and transparency in clear grades. While PC is generally more expensive than ABS, it provides superior mechanical and thermal performance, making it a cost-effective upgrade in applications where durability, clarity, or heat resistance are critical.

PC-ABS is a blend of PC and ABS, combining the strength and heat resistance of PC with the moldability and cost-effectiveness of ABS. When your application requires higher impact strength, better heat resistance, or improved toughness at low temperatures—where standard ABS might fall short—PC-ABS is the superior choice.

For harsh outdoor and UV-exposed applications like automotive exteriors, opt for Acrylonitrile Styrene Acrylate (ASA). Like ABS, ASA has good chemical resistance and high-impact strength, but it offers superior UV stability, weather resistance, and longer-term color retention—even compared to ABS with UV additives.

At HLH Rapid, we offer an extensive selection of resins to meet your custom injection moulding needs, including ABS, PC, PMMA, PP, POM, HDPE, and more. To begin your next project, simply upload your CAD drawings using our site contact form and provide the project details, such as quantity, material choice, and any surface finish requirements. Our dedicated team will respond with a quote within 48 hours or less.