Get custom SLA 3D printed prototypes and production parts from as fast as 2 days.

Stereolithography or SLA is a resin-based 3D printing technology that produces highly accurate, high resolutions parts with an excellent smooth finish. The combination of high speed, low-cost per part and well-established materials makes stereolithography an ideal choice for prototypes and low volume production.

Source accurate to CAD and fine-detailed parts with HLH Rapid’s SLA 3D printing service.

| Our Capabilities | Industrial SLA |

|---|---|

| Maximum Build Size | 800 x 800 x 550 mm (31.5″ x 31.5″ x 21.6″) |

| Lead Time | 2-3 days |

| Resolution | ± 0.2mm |

| Prototyping Applications | High aesthetic and accurate to CAD prototypes |

| End-Use Applications | Low-volume, fine detailed parts |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Sanding | All | – | Sanding SLA printed parts is often the best way of smoothing edges, removing blemishes, and getting rid of any leftover support marks. |

| Spray Painting | All | Black, Pantone/RAL colours | Spray painting is a quick way to colour parts. It can also reach areas that cannot be reached with a brush. |

| Plating | ABS | Metallic | Plating is method of adding a thin layer of metal of the outer layer of a material. It is used to harden, decorate and improve wearability of parts. |

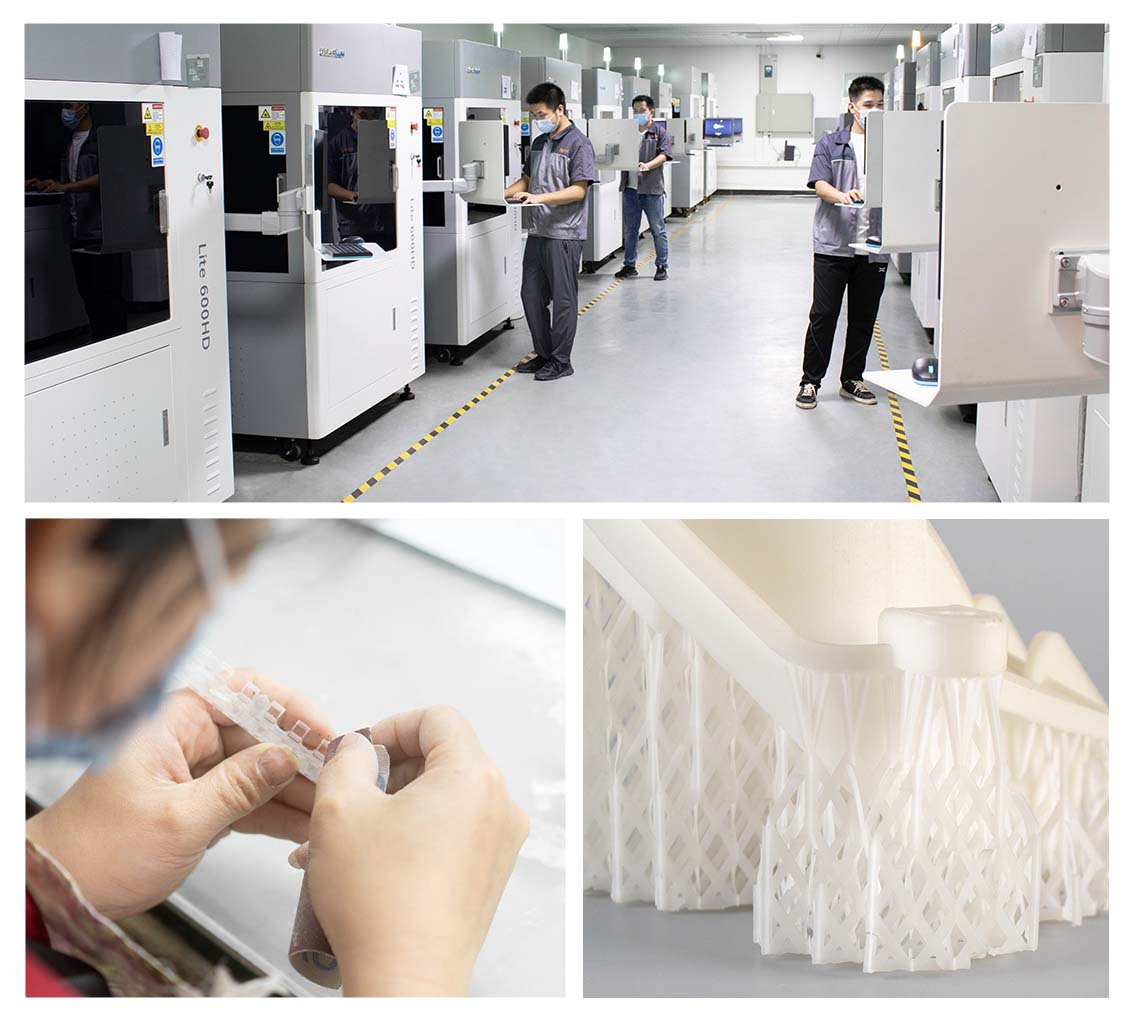

SLA 3D printing builds parts one layer at a time using a highly accurate UV laser to solidify one layer of photosensitive resin, which makes the parts accurate and in good surface. The parts need to be built with support structures which are removed during post process. View the full overview of Stereolithography.

To achieve better part quality and end results, it is important that you design your part for the process. Learn how to design overhangs. assembly parts and more in our SLA 3D printing design guide.

Wide Range of Materials – stereolithography offers a vast material selection with a range of properties.

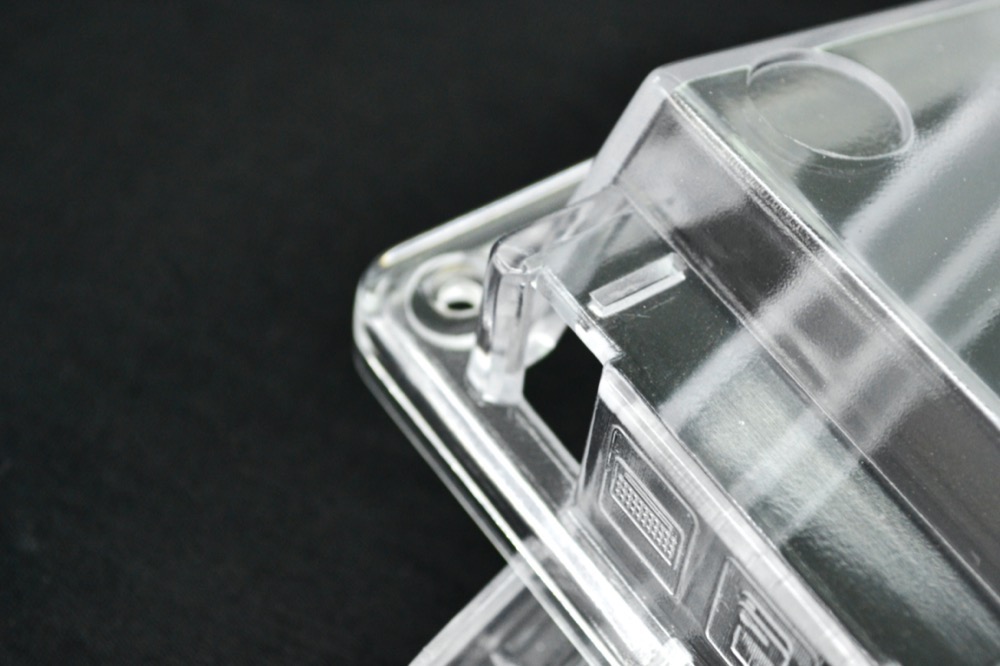

Finest Detailing – SLA is one of the best 3D printing technologies for creating very accurate and finely detailed parts.

Rapid Turnaround – Because SLA can create complex and multi-material parts in a single operation, significantly less build time is needed vs. traditional manufacturing.

Smooth Finish – SLA creates parts with an excellent finish which remarkably resembles end use items like injection moulded parts.

Generally Brittle – SLA parts are generally brittle and not suitable for many functional applications.

Degradation Over Time – Due to the photosensitive nature of SLA resins, SLA parts will experience degradation over time when exposed to sunlight.

Requires Support Structures – SLA prints always require support structures, which must be removed in the post-processing stage.

Stereolithography or SLA 3D printing is the most common resin 3D printing process. It has become very popular over the years due to its ability to produce highly accurate and watertight prototypes and end-use parts in a range of materials with fine features and smooth surfaces.

SLA (or stereolithography) is a plastic 3D printing process that uses light-reactive thermoset materials called “resin.” The process offers a wide range of plastic material options that are often categorized by different material properties, including:

The many advantages of SLA 3D printing have made it a choice for many applications across different industrial sectors for many years, including:

SLA 3D printers use UV lasers to trace out the cross-sections of the model and form a object. This process creates a very high resolution, detailed printout, but it requires a longer print time. On the other hand, FDM (fused deposition modeling) creates parts additively using a filament. The process results in a lower quality printout, but they can do so faster. View the full comparison guide here.