Get custom SLS printed parts and prototypes from as fast as 2 days.

Selective Laser Sintering (SLS) is an industrial 3D Printing technology that builds accurate and durable parts from Nylon PA 12. The combination of low cost per part, established materials and speed makes SLS a go-to solution among engineers for rapid prototypes, functional end-use parts and low-to-mid volume production.

| Our Capabilities | Industrial SLS |

| Max build size | 400 × 400 × 450 mm (15.7″ × 15.7″ × 17.7″) |

| Lead time | From 2 days |

| Layer thickness | 100 μm (0.1 mm) |

| Tolerance | Standard ±0.3 mm, tightest ±0.2 mm |

| Quantity | 1 – 10,000 parts |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

| Applicable Materials | Colors | Description | |

|---|---|---|---|

| As Printed | All | Natural | As printed or deburr is the default SLS finish, parts cleaned of loose powder and sharp edges. |

| Dyeing | PA12, PA12-GF, TPU | Black, Pantone/RAL colours | Dyeing is the fastest and most cost-effective way to colour SLS parts, mainly used to improve aesthetics. |

| Spray Painting | All | Black, Pantone/RAL colours | When dyeing isn’t suitable, spray painting provides an effective alternative for achieved coloured SLS parts. |

| Vapour Smoothing | PA12, TPU | – | Vapour Smoothing smooths and seals the surface of SLS parts and reduces crack initiation points, enhancing elongation at break, impact resistance and fatigue strength. |

TECHNOLOGY OVERVIEW

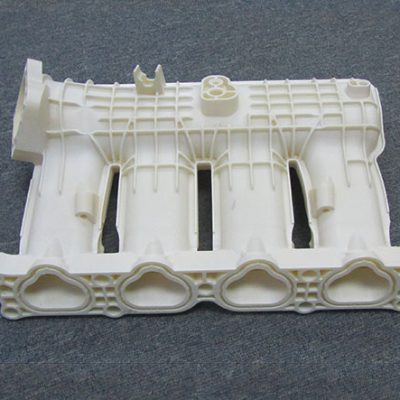

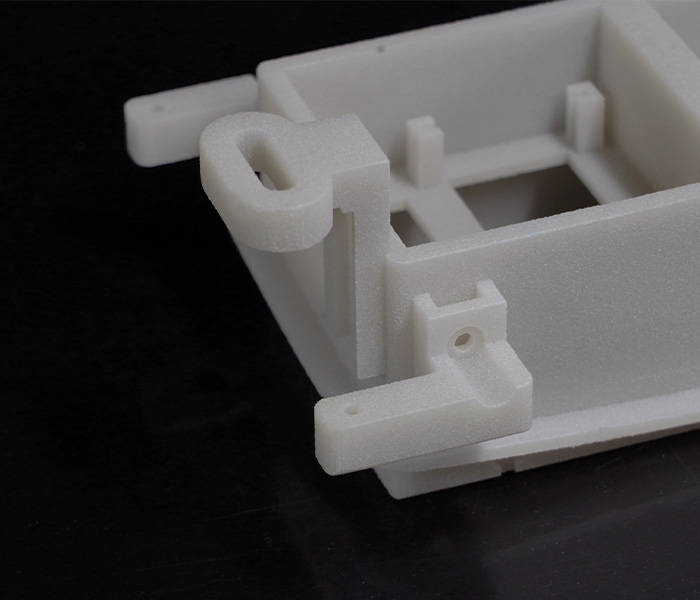

SLS 3D printing is a mature and stable process that uses a high-powered laser to fuse (sinter) powdered material together layer by layer, based on a 3D CAD model to form a solid part. Due to the surrounding powder, SLS can achieve overhangs and complex features without support structures. This powder bed technology rivals injection moulding prices for short production runs of small parts.

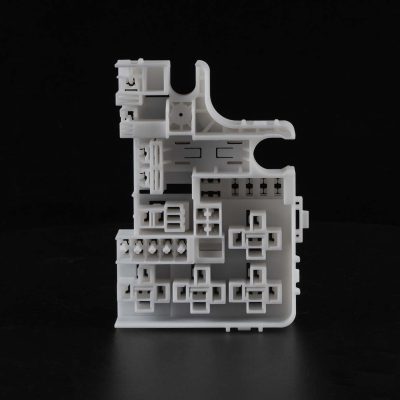

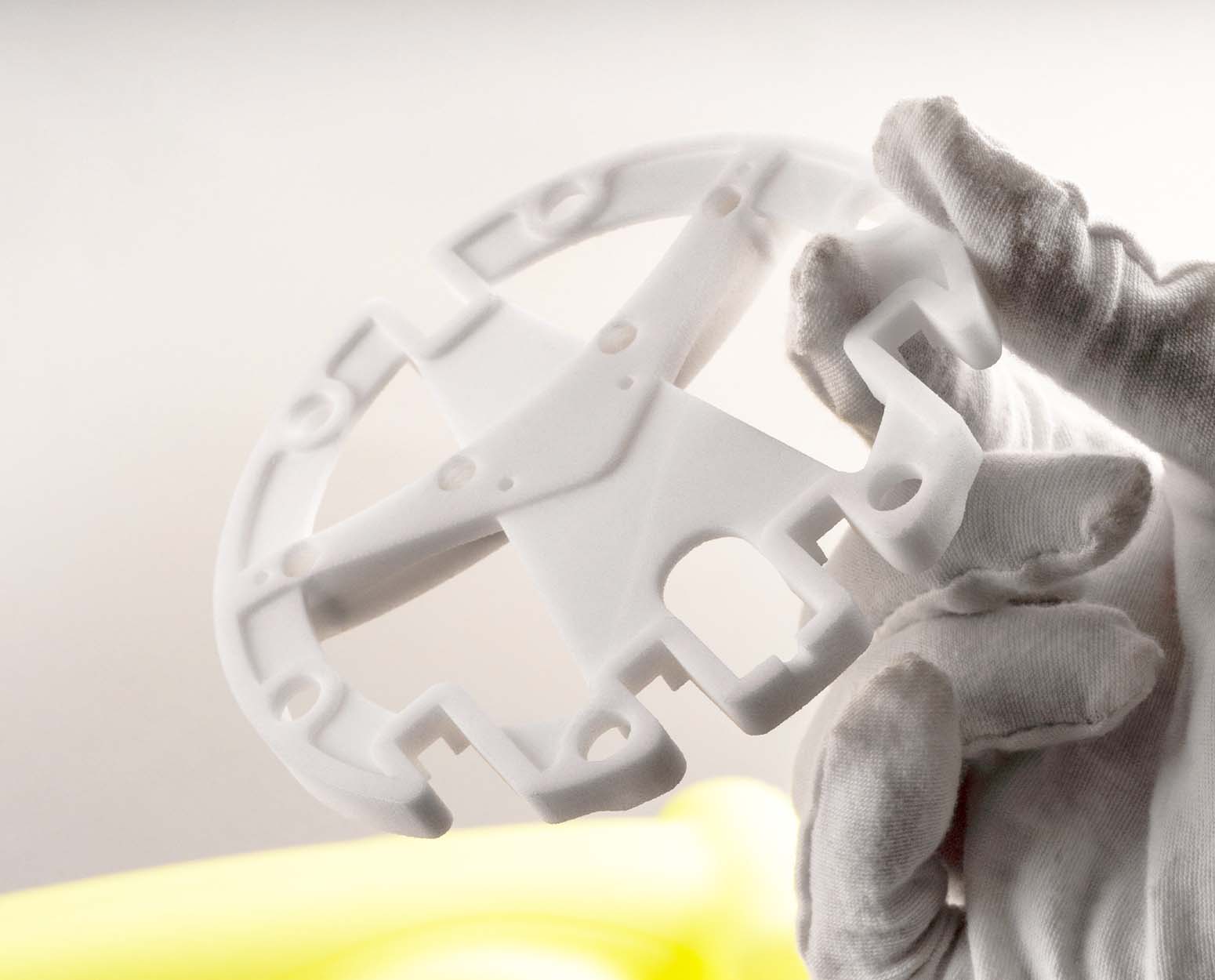

Unlike other 3D printing processes, selective laser sintering allows parts to be densely arranged and stacked throughout the build volume, fully utilizing the X, Y, and Z axes. This makes it an ideal solution for cost-effective, low-to-mid volume production of small parts.

SLS does not require support structures, allowing for greater design freedom. To take full advantage of this technology, it is important that you design for the process. Learn actionable design tips here.

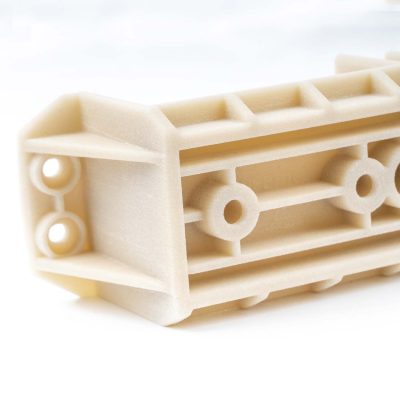

Industrial SLS produces strong, durable parts with excellent dimensional accuracy, using engineering-grade materials suitable for some of the most demanding applications.

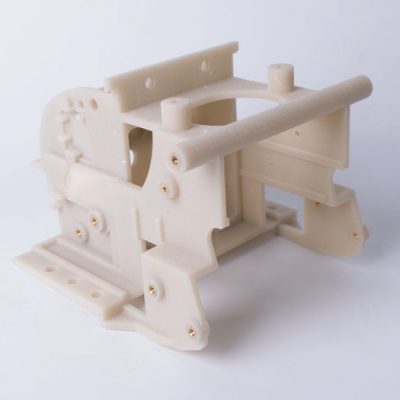

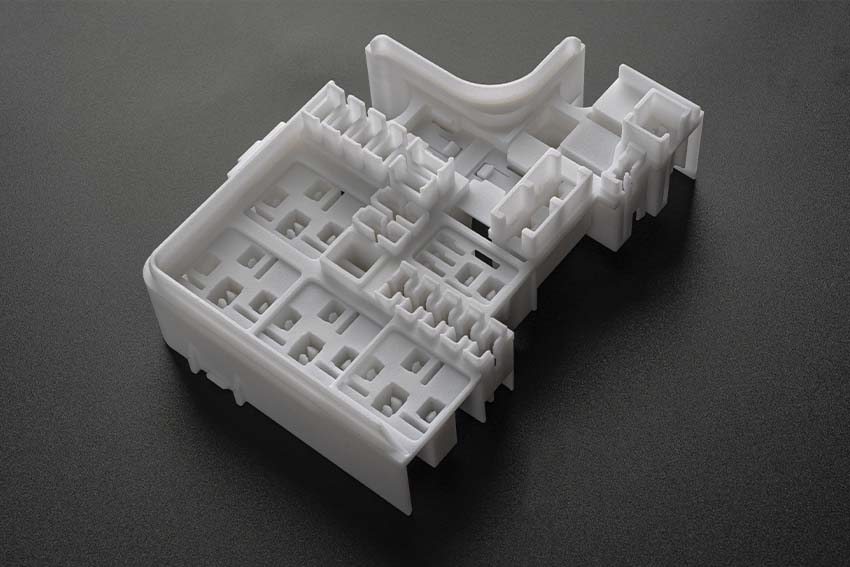

On-demand Selective Laser Sintering allows you to prototype in days using industrial-quality materials—from concept models and functional test parts to rapid design iterations.

SLS is an excellent choice for low-to-medium batch production because it can print multiple parts simultaneously without supports, delivers industrial strength parts and requires no tooling cost.

Industrial SLS printers, like the ones we use at HLH, can handle large parts, with a maximum build size of 15.7 × 15.7 × 17.7 inches (400 × 400 × 450 mm). We also frequently print larger models—split into multiple sections and assembled after printing.

SLS is widely used for rapid prototyping and end-use applications across many industries. Some top examples include:

There is no inherently “better” 3D printing process.

Both SLS and SLA can produce industrial-grade parts, but SLA (Stereolithography) has some important caveats compared to SLS. Selective Laser Sintering builds stronger, more functional parts that are ideal for jigs, fixtures, end-use parts and high strength prototyping. The surrounding powder also allows it to produce overhangs and complex features that may be difficult or impossible to achieve with SLA.

SLA, on the other hand, is better for producing small, fine features. It also offers a wider range of resins and finishing options in comparison with SLS, making it suitable for aesthetic models and on-demand parts where detail and surface finish are critical.