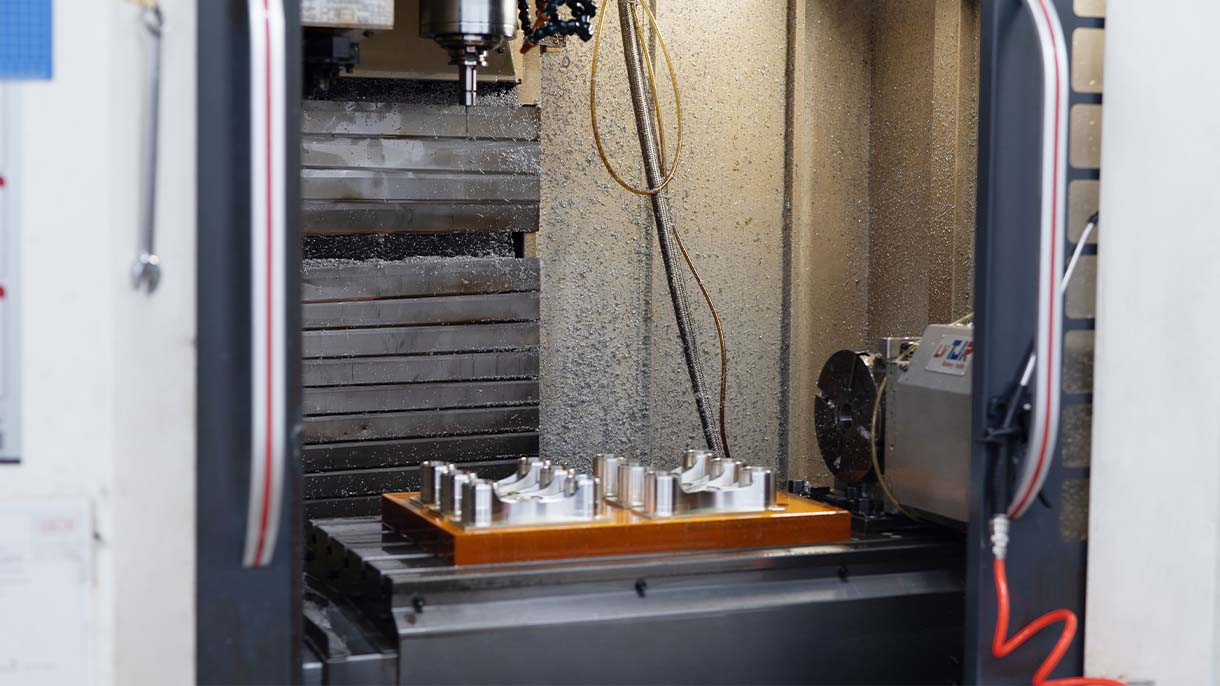

Aluminum is the most widely used metal in CNC machining due to its good mechanical properties and excellent balance of strength, weight, conductivity, machinability, resistance to corrosion and cost. Here’s why it’s the top choice in many industries:

Aluminium Machining Benefits

There are many aluminum alloys available, spanning various grades from the 1000 to 8000 series, which can be challenging to navigate. At HLH, popular aluminium alloys for CNC machining, include:

| Temper | Tensile Strength | Elongation | Hardness | Notes | ||

|---|---|---|---|---|---|---|

| AL 7075 | T6 | 510–540 MPa | ~5% | 150–180 HB | Aluminum 7075 T6 offers superior strength-to-weight ratio, but when not required, you’re better off with a cheaper alloy. | Data Sheet |

| AL 6061 | T6 | 290–310 MPa | ~6% | 95–105 HB | All rounded but not suitable for high-stress aerospace applications without extra treatments. | Data Sheet |

| AL 6082 | T6 | 300–350 MPa | ~8% | 90–110 HB | Thin ribs or fine features in Aluminium 6082 designs can be challenging to machine due to the tendency to bend or distort when clamping or under cutting forces. | Data Sheet |

| AL 5052 | H32 | 210–260 MPa | ~7% | 75– 90 HB | Excellent corrosion resistance; relatively low strength limits use in structural components. | Data Sheet |

| AL 5083 | H116 | 300–350 MPa | ~12% | 85–105 HB | Exceptional resistance to seawater corrosion but not heat-treatable for significant strength gains. | Data Sheet |

| AL 2024 | T4 | 400–470 MPa | ~10% | 120–150 HB | Poor corrosion resistance; must be coated or anodized; difficult to weld without strength loss. | Data Sheet |

*Please note the values are approximate averages and may vary depending on the material’s thickness and form (e.g., plate, extrusion, forging).

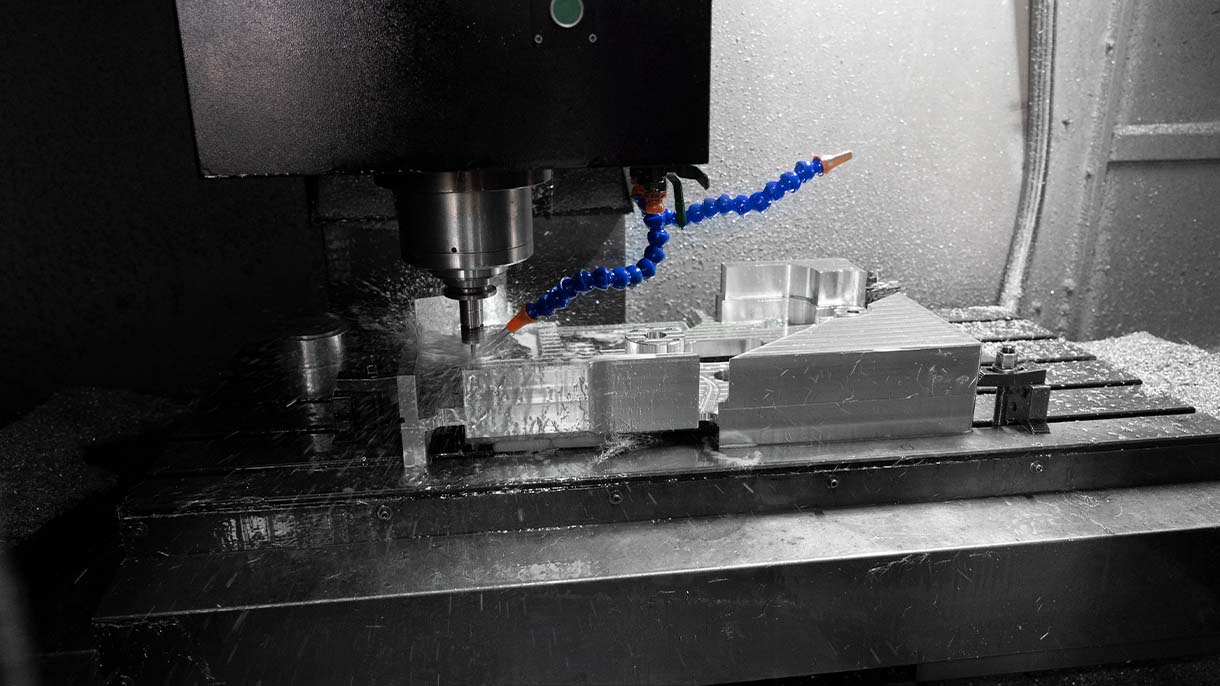

Aluminium is a relatively easy material to machine due to its low cutting forces and high machinability, generally making it easier to work with than steel. Although it is a soft, lightweight material with many advantages, it can present machining challenges such as built-up edge formation, chip adhesion, and poor surface finish under improper cutting conditions. Below are some key considerations.

1. Material Properties

Aluminum alloys generally have a high coefficient of thermal expansion, and are susceptible to temperature-induced dimensional changes during machining and processing. Therefore, it is important to use proper coolants and tightly control cutting parameters to minimize thermal distortion.

2. Residual Stress

Internal stresses can cause parts to warp, bend, or distort during machining or when released from a fixture—especially in alloys like 6082 and 7075. Allowing sufficient cooling time between machining operations and carefully controlling cutting parameters helps reduce distortion.

3. Improper Clamping

Poorly designed or uneven clamping can apply excessive force on the part, increasing the risk of deformation. Using soft jaws, proper fixture design, and evenly distributing clamping pressure are essential to maintaining part integrity.

4.Cutting Force and Heat

Tool friction and cutting forces generate localized high temperatures, causing expansion or contraction of the material. This thermal effect can impact dimensional accuracy and surface finish if not properly managed with coolant and optimized cutting parameters.

Anodizing is one of the most common finishing options for aluminum machining. It is highly compatible with most aluminum alloys—especially 6061, 7075, 2024, and 5052, which anodize very well. This finish offers strong corrosion protection, increases durability, and enhances the overall appearance of metal parts.

Other popular finishes for aluminum machining include bead blasting, nickel and chrome plating, brushing, polishing, sandblasting and painting. Aluminium is a very versatile metal that is generally compatible with all the most common mechanical, chemical, and electrochemical finish techniques [view all cnc finishes available at HLH].

Aluminium is generally a cheaper option compared to metals like Titanium, Brass and Copper, costing around $2 to $5 per kilogram. While raw aluminium is slightly more expensive than steel per kilogram, it can be machined faster, which often translates to a lower overall price for machined aluminium parts compared to steel. That said, specialty alloys such as AL7075 command higher prices per kilogram and require longer machining times than standard aluminium alloys. This can sometimes result in an on-par or higher total cost compared to standard structural steel parts.

Simple jobs (e.g., aluminum brackets) using 3-axis CNC machining typically require less time, fewer tools, fewer setups, and minimal programming. In Europe, you might expect to pay between $25–$80 per hour, while in China, rates generally range from $10–$35 per hour. For more complex jobs (e.g., aerospace components that demand 5-axis machining, tight tolerances, multiple setups, or specialized tools), hourly rates can range from $80–$150 per hour in Europe and $20–$65 per hour or higher in China.

Simply send your 3D CAD to kick off your project. Fast lead times, no MOQ.

The best savings come with batch production. With aluminum machining, the price per piece can drop significantly as batch sizes increase. Whereas, with aluminium 3D printing, the cost per unit remains relatively the same, even with higher quantities.

At HLH Rapid, we specialise in precision machining, and can work with aluminium as well as a variety of metal and plastics that you can choose from for your custom CNC project. For expert advice, support or to get a quote, get in touch with us at info@hlhrapid.com or upload your CAD drawing to our Get a Quote Form to kick off your project.