The term injection moulding encompasses several processes that inject molten resin into a mould to form plastic parts. Common types of injection moulding include thermoplastic injection moulding, liquid silicone rubber (LSR) moulding, overmoulding, 2K or two-shot moulding, and insert moulding — with thermoplastic moulding being the most popular. If you’re involved in plastic manufacturing, understanding thermoplastic injection moulding is definitely a good place to start.

When people say plastic injection moulding, they often mean thermoplastic injection moulding. This process involves injecting melted thermoplastic resin into a mould cavity, where it cools and solidifies before being ejected as a finished plastic part. It is a highly repeatable and cost-effective method for producing high volumes—from thousands up to millions of parts—efficiently, while maintaining the original material properties with excellent precision.

Thermoplastics are notably favoured in injection moulding because they can be reheated and reshaped repeatedly, which makes it particularly advantageous for recycling and reusability. They can also be easily shaped to accommodate intricate designs, which is particularly beneficial for industries where aesthetics and functionality must meet in harmony.

The process is essentially made up of two stages:

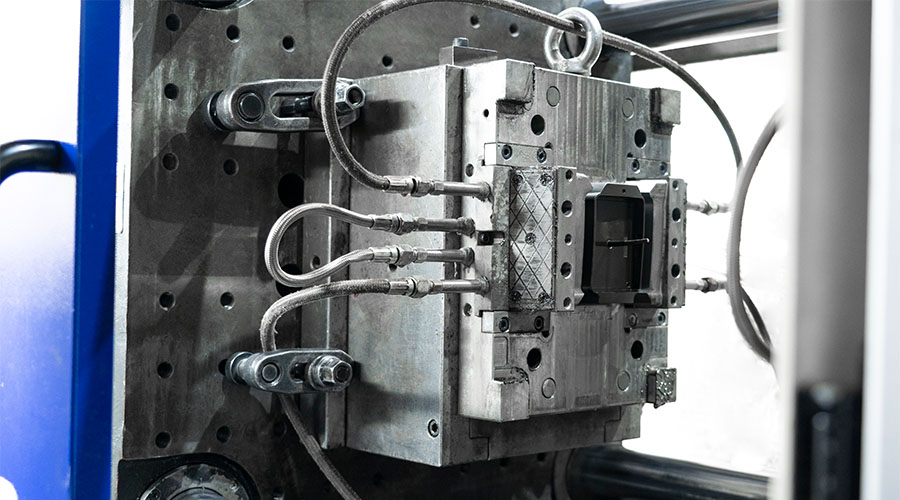

1. Tooling Fabrication or Mould Production: The process begins with designing and CNC machining the mould, usually from steel or aluminium. This mould includes critical features like runners, gates, and cavities that guide the molten plastic to form the final part. Once the mould is complete, it is installed into the injection moulding machine to prepare for production.

2. Part Production: Production starts by feeding thermoplastic resin pellets into a heated barrel, where they melt into a molten state. The molten plastic is then compressed and injected through the runner system and gates into the mould cavity. After cooling and solidifying, the finished part is ejected from the mould using ejector pins, ready for the next cycle.

The initial tooling is usually the most costly part of an injection moulding project, with prices between £2,000 and £5,000 for basic prototype or low-volume moulds, and £6,000 upwards for larger, more intricate, or high-production tools. Once the mould is completed, you can benefit from the low per-part cost and fast production cycles that make injection moulding so cost-effective at scale. Thermoplastics used in the process typically cost between £1 and £5 per kilogram—with commodity plastics at the lower end—and part costs generally start around £0.10 to £10, increasing depending on quantity and complexity.

Thermoplastic injection moulding, overmoulding, insert moulding, 2K or 2-shot moulding

The main difference between thermoset and thermoplastic injection moulding lies in how the materials behave under heat. In thermoset injection moulding, a liquid or partially cured resin is injected into a hot mould, where it undergoes a chemical cross-linking (curing) reaction that irreversibly hardens the material. Once cured, thermosets cannot be remelted or reshaped.

In contrast, thermoplastic injection moulding involves melting plastic pellets and injecting the molten material into a cooler mould where it solidifies. Thermoplastics do not chemically cure—they harden simply by cooling, which means they can be remelted and reprocessed multiple times.

What’s an ideal thermoplastic resin? When choosing a material for your part, select one that effectively balances a range of key properties (mechanical strength, physical characteristics, chemical resistance, UV resistance, etc.) to meet the specific demands of your application. There is no one-size-fits-all resin, but understanding material properties can help guide your choice.

Acrylonitrile Butadiene Styrene (ABS): A tough, impact-resistant thermoplastic with good strength and rigidity. It’s famously used to make LEGO bricks and other high durability applications including helmets, automotive parts, and protective housings.

PMMA (Acrylic): High transparency material with excellent optical properties, durability, and ease of processing. When you need a clear, transparent thermoplastic for optical clarity and UV resistance, PMMA is the best choice.

Polycarbonate (PC): A transparent thermoplastic known for its very high impact resistance and toughness. It’s widely used in applications such as phone screens, bulletproof and defense shields, safety goggles, and automotive parts where durability and strength are critical.

Acetal (POM): A strong, stiff material with low friction and excellent wear resistance, making it ideal for precision mechanical parts like gears, bearings, and fasteners.

Nylon (PA): A strong, wear-resistant material with good mechanical properties, available in many grades. It’s a commonly used for gears, bearings, bushings, automotive components and industrial machinery where durability and abrasion resistance are important.

Polyetheretherketone (PEEK): A premium high-performance plastic with outstanding strength, heat resistance, and chemical resistance. While it is on the higher end of the price spectrum, its unique properties make it ideal for demanding applications such as aerospace components and medical implants.

TPU: A flexible thermoplastic elastomer with excellent abrasion resistance, elasticity, and chemical resistance. It’s often used for overmoulding applications as well as stand-alone injection moulded parts like seals, footwear and automotive interior parts.

Polypropylene (PP): An low cost thermoplastic known for its good chemical resistance and flexibility. It is ideal for applications where cosmetics and rigidity aren’t priorities and is widely used for living hinge designs due to its excellent fatigue resistance.

High-Density Polyethylene (HDPE): An affordable thermoplastic known for its excellent chemical resistance and good impact strength. It is used for agricultural pipes, plumbing components and containers.

Low-Density Polyethylene (LDPE): LDPE is less expensive than HDPE but is also softer, less durable, and less rigid. Because of these characteristics, it is commonly used for squeeze bottles, flexible packaging, and other applications that require flexibility.

Polyvinyl Chloride (PVC): A versatile thermoplastic available in both rigid and flexible forms. Rigid PVC is commonly used in construction for pipes, window frames, and siding due to its strength and durability.

Glass Fibers (GF): At HLH, glass fibers are among the most commonly used additives in thermoplastic injection moulding projects. Depending on the percentage of fill (e.g., 30%, 50%, 70%), they can significantly enhance the strength, stiffness, and dimensional stability of plastic parts. However, it’s worth noting glass fiber is abrasive, and higher fill levels can accelerate tool wear over time. Besides glass fibers, other common fillers include talc and calcium carbonate.

UV Stabilizers: PMMA, PTFE (Teflon), and PVDF are inherently UV-resistant polymers. Other thermoplastics like ASA and PC rely on additives such as HALS (Hindered Amine Light Stabilizers) and carbon black to enhance UV stability, protect the material against degradation, and extend its lifespan.

Flame Retardants: With specialized additives, certain types of ABS, PC, and PBT can resist ignition and slow the spread of fire, enabling these plastics to meet safety standards required in electrical, automotive, and construction applications.

Colourants: Added to thermoplastics to achieve a wide range of colours and effects, colourants can be in the form of pigments or dyes. They not only provide aesthetic appeal but can also alter the plastic’s properties such as thermal stability and UV resistance.

Surface finish in injection molding plays a critical role in both aesthetics and functionality. There are two primary ways to achieve desired finishes:

While plastic injection molding offers many advantages, designing for the process can be challenging. That’s why at HLH, we typically perform a Design for Manufacturing (DFM) and tooling feasibility report before proceeding with tooling production. Simple design modifications such as optimizing rib thickness, adding draft angles and carefully designing features like bosses and undercuts can help reduce defects like sink marks, warpage, and part failure. Explore our design resources to improve your moulded part performance:

At HLH Rapid, we offer a wide range of thermoplastics and deep expertise in mould tooling to support your custom injection moulding projects. To kick off your next project, simply upload your CAD drawings to our site contact form and provide the project details, such as quantity, material choice, and any surface finish requirements. Our dedicated team will respond with a quote within 48 hours or less.