There are many different thread types, and it can be confusing to know which one to use for your project. In this guide, we will explain the differences between thread types—M, UN, NPT, BSPT, BSW and ACME—and help you decide which is best for your design and manufacturing.

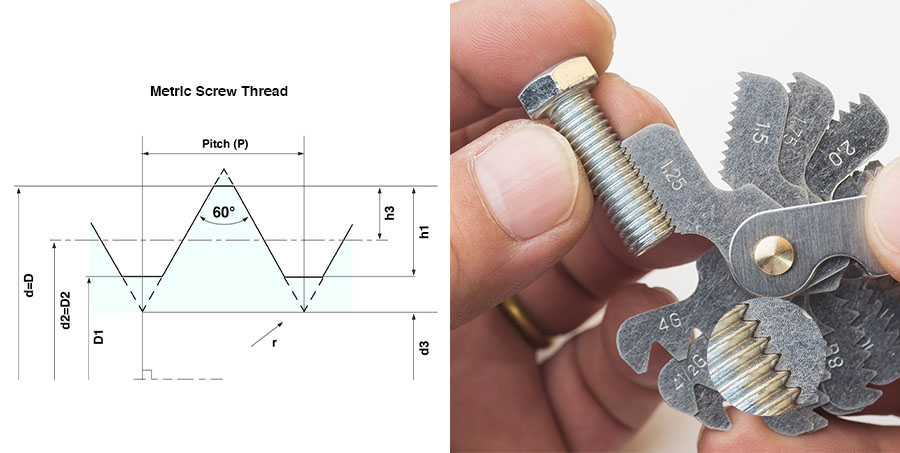

Metric threads (M)

Metric threads are the metric international standard that follows ISO. It’s the most commonly used type of threads worldwide to bolt standard assemblies together. The ISO metric screw thread uses a 60° pitch angle, and uses pitch to define the thread, not its crest (flat part). Example, M6 x 1.0, indicates an M6 thread with a pitch of 1.0 millimeters.

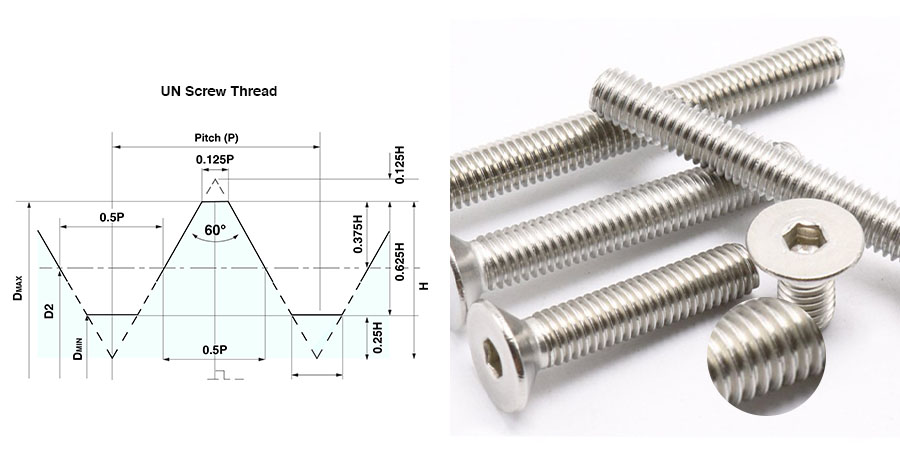

Unified Thread (UN) — UNC, UNF, UNEF

UN are an imperial (inch-based) thread standard with a 60° thread angle, they are available in coarse (UNC), fine (UNF), and extra fine (UNEF) series. In more specialized applications, such as aerospace components and precision instruments, an extra fine pitch (UNEF), with even more threads per inch than UNF, may be used.

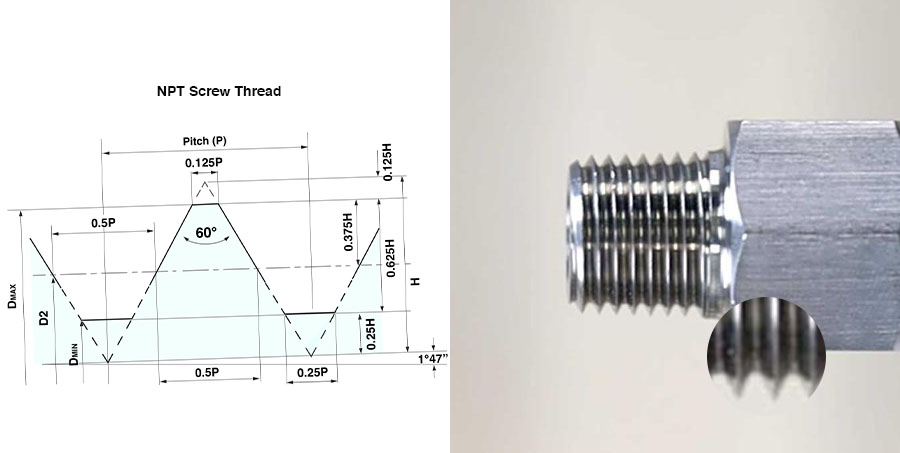

National Pipe Thread (NPT) — NPT/NPS/NPTF

Like UN, national pipe thread is an American standard for a tapered thread profile that uses a 60° thread angle, but with an added taper of 1° 47′ (1.7899°) per side. This taper allows the thread to compress together as they are tightened, creating a seal that prevent leakage, making it ideal for pipe fittings and gas or fluid systems. NPT (National Pipe Tapered) is the most common for general plumbing and requires sealant, NPS (National Pipe Straight) uses parallel threads and relies on gaskets or o-rings to seal, and NPTF (National Pipe Tapered Fuel) is designed for dry-seal applications, forming a leak-proof metal-to-metal seal without sealant.

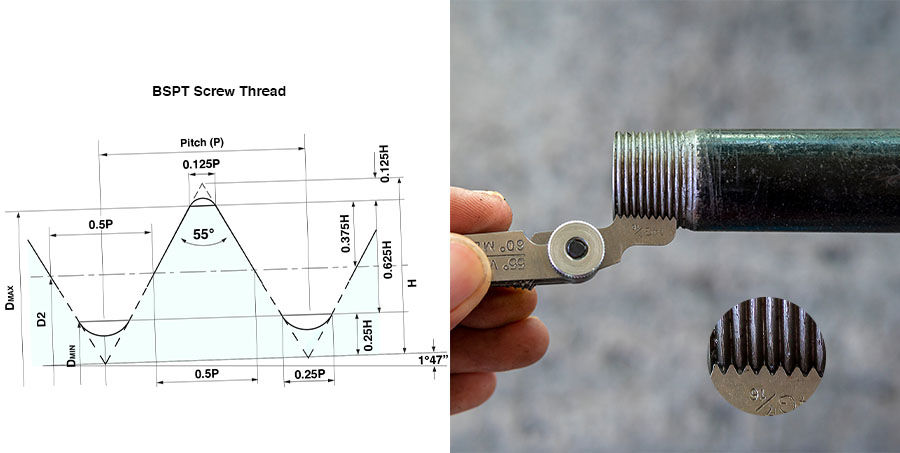

British Standard Pipe (BSPT)

BSPT (British Standard Pipe Tapered) is a thread standard primarily used in the United Kingdom, Europe, and other regions for threaded pipe fittings. Like NPT, it features a tapered profile that enables the threads to compress and form a tight, leak-resistant seal. However, BSPT differs in using a 55° thread angle instead of the 60° angle used in NPT, making them not interchangeable despite similar appearances.

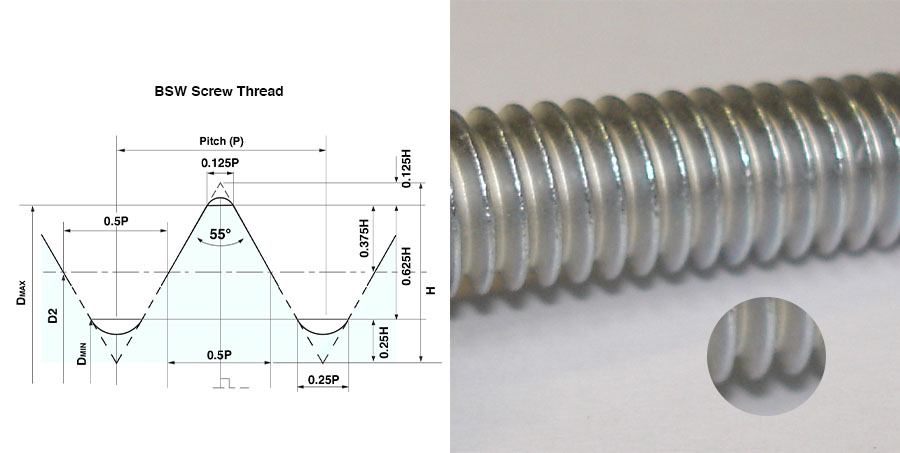

British Standard Whitworth (BSW)

BSW is another thread standard primarily found in the United Kingdom and commonwealth countries. The BSW thread profile has a rounded crest and root. Like BSPT, it uses a distinct 55° thread angle. While less commonly used today, understanding BSW is useful if you need replacement parts or are working with vintage or specialized equipment where these threads may still be in use.

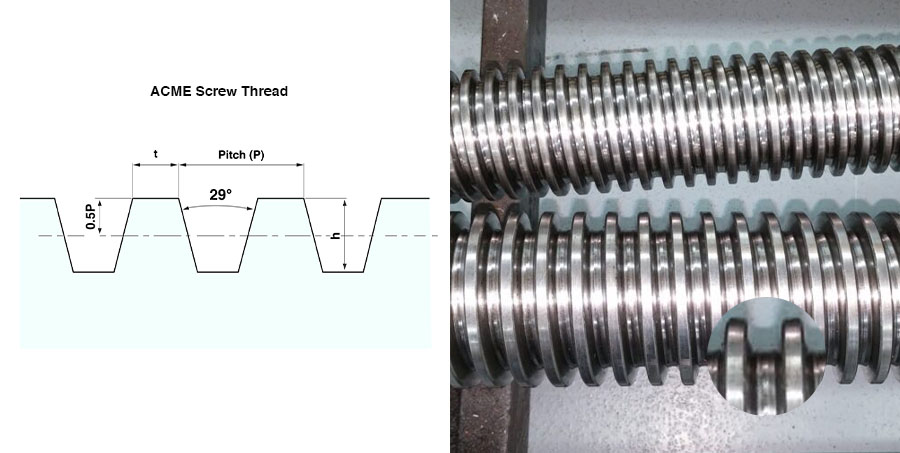

ACME

ACME threads are a type of trapezoidal thread with a 29° thread angle and a flat crest and root. They are among the strongest symmetric thread profiles and are commonly used in lead screws found in CNC milling and turning machines, conveyors, and aircraft flaps, where precise movement of heavy loads is required.

| Thread Type | Commonly Used For | Region | Key Feature |

|---|---|---|---|

| M (Metric) |

| Worldwide (especially Europe and Asia) | ISO standard, widely compatible 60° included angle, non-tapered thread |

| UNC |

| USA, Canada | Easy assembly, common in general usage American thread standard 60° included angle, non-tapered thread |

| UNF |

| USA, Canada | Tight tolerances, used in precision work American thread standard 60° included angle, non-tapered thread |

| NPT |

| USA, Canada | Not compatible BSPT Self-sealing for fluid/gas 60° included angle, tapered thread |

| BSPT |

| UK, Commonwealth Countries, Europe | Not compatible with NPT Not requiring sealant 55° included angle, tapered thread |

| BSW |

| UK, Commonwealth Countries | Rounded thread profile Older standard 55° included angle, non-tapered thread |

| ACME |

| Global | Flat crest and root profile, trapezoidal profile Heavy-duty usage 29° included angle, non-tapered thread |

HLH Rapid is rapid prototyping specialist with years of experience manufacturing custom threaded parts. To get started on your next project, simply upload your 3D CAD drawing to our Get a Quote Form, and our team will get back with a quote within 24 hours or less.