Get custom injection moulded prototypes and production parts in as fast as 2 weeks.

Injection moulding is our top choice for producing low-volume plastic parts. Thanks to its high-precision, repeatability, and cost efficiency at scale, our plastic injection moulding services have been used to make a variety of parts from the smallest medical insert up to large automotive & aerospace parts.

| Our Capabilities | Description |

| Machine size | 50 – 3000 ton |

| Mould tool material | aluminium and steel (various grades) |

| Shot life | 500 to 1M+ shots (MOQ of 1) |

| Mould type | single cavity, multi cavity and family mould |

| Lead time | T1 samples as fast as 2 weeks |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| SPI Mould Finishes | All | SPI A1-3, B1-3, C1-3, D1-D3. Read the Guide to SPI finishes. |

|

| Painting | All | Black, Pantone/RAL colours | Painting is a method of adding colour to a part. It is often used to increase the aesthetics of a part. |

| Chrome Plating | All | Silver-gray metallic | Chrome plating is used to increase corrosion resistance or surface hardness of a part, ease the maintenance process or for purely decorative purposes. |

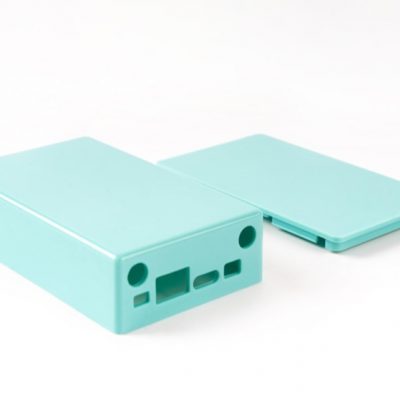

| Client | Sol Reader; San Francisco, USA |

| Product | E-Ink VR Headset |

| Project | Rapid tooling & injection moulding, silicone overmoulding |

| Mould material | P20 steel |

| Part material | Nylon (PA) 610, TPSiV®Silicone |

| Surface finish | Semi-gloss SPI-B1, VDI-24, VDI-27, polishing + rubberized paint |

| View details | Read the full article |

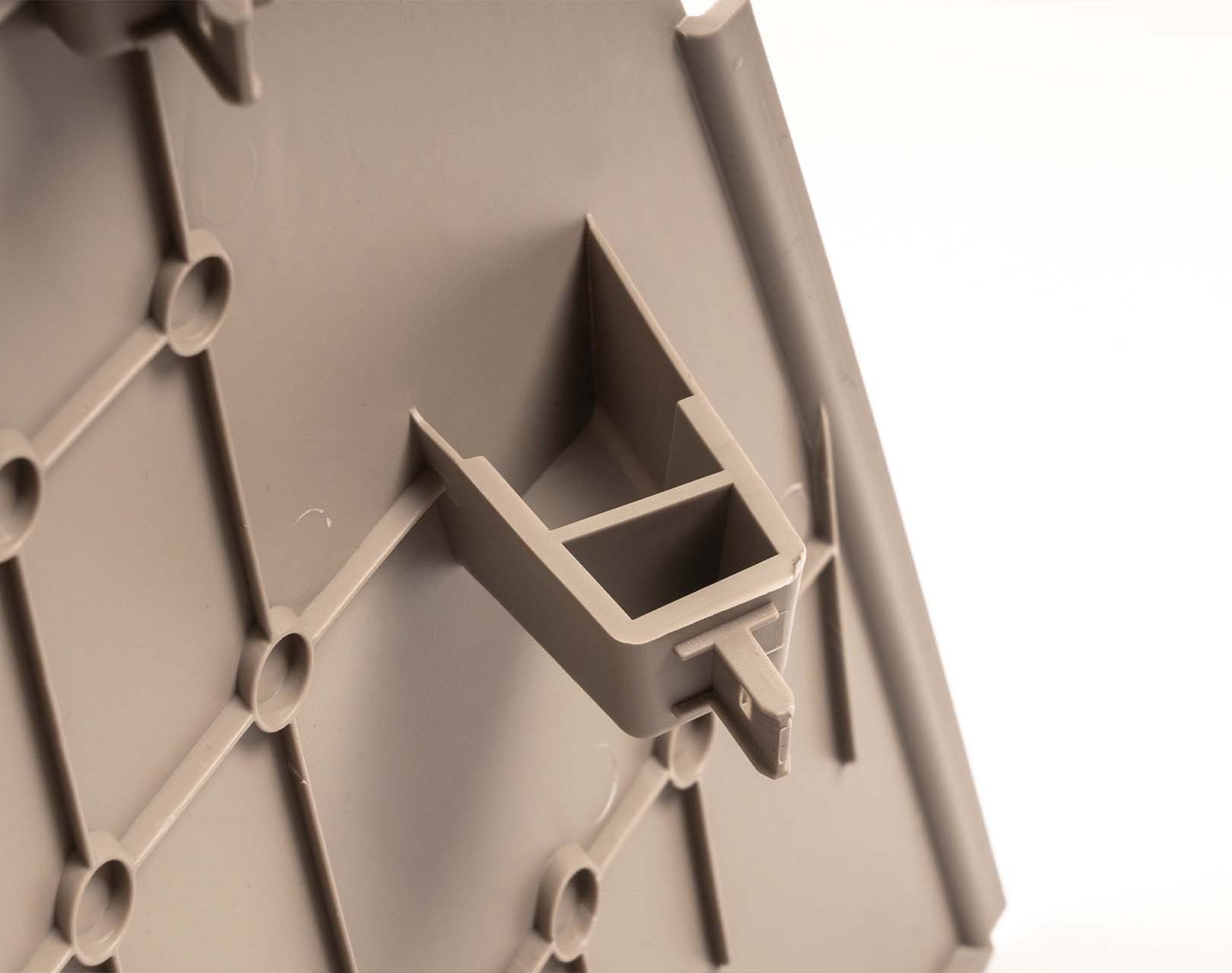

The injection moulding process requires an injection moulding machine, raw plastic material, and a machined mould. The raw plastic material is first melted in the injection unit then injected into the mould — most often machined from steel or aluminium — where it cools and solidifies into the final plastic part.

| Grade Size | 0.5-3mm | 3-6mm | 6-30mm | 30-120mm | 120-400mm | 400-1000mm | 1000-2000mm | 2000-4000mm |

|---|---|---|---|---|---|---|---|---|

| Fine | 0.05 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.5 | / |

| Medium | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.8 | 1.2 | 2 |

Several factors such as wall thickness, draft angles and corner radii, can affect the quality of the final injection moulded part and the repeatability of the process. For better part quality, learn to design for the process here.

Injection Moulding vs Vacuum Casting

Vacuum (urethane) casting offers a lower front-end cost with a higher unit price, while injection moulding demands a higher front-end cost, but a significantly lower unit price. With higher volume production runs, you will simply not see the same ROI with vacuum casting than you will with injection moulding.

Rapid Injection Moulding is Used For

Producing low-volume (up to 100,000) quality production parts and prototypes from real materials. Rapid injection moulding is used for prototyping, bridging and low volume production run parts in less time and a reduced cost than full production mould.

Advantages of Injection Moulding

Injection moulding is a mature manufacturing process that allows for plastic parts to be produced in large volumes. The process involves melting plastic pellets that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Rapid injection moulding is the process of making injection moulds for prototyping, bridging, and short production run parts in less time and a reduced cost than full production moulds.

Mould Cost: Typically, the tooling costs is between $2,000 – $10,000. However, depending on the complexity of the project, type of tool, and other factors, it can go well over $10,000.

Part Cost: The unit cost is what makes the initial investment in injection mould tools worthwhile. You can expect the cost per unit to range between a few pennies to a few dollars.

Injection mould tools can last between 100 to over 100,000 and even 1M+ cycles. The life span of an injection mould depends on the mould material, mould structure design, maintenance, time between production runs and operating conditions.

Injection moulding is one of the most popular and versatile manufacturing technologies for producing mid-to-high volumes of plastic parts. It is widely used in many industries, including: