Fast & Affordable — Get custom sheet metal prototypes and parts from as fast 5 days.

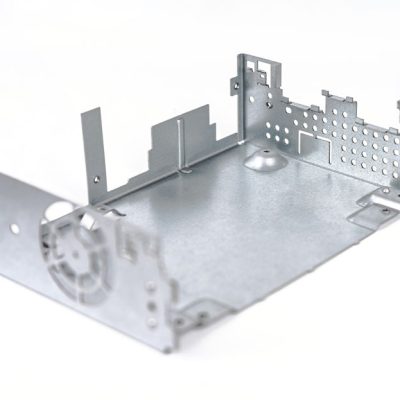

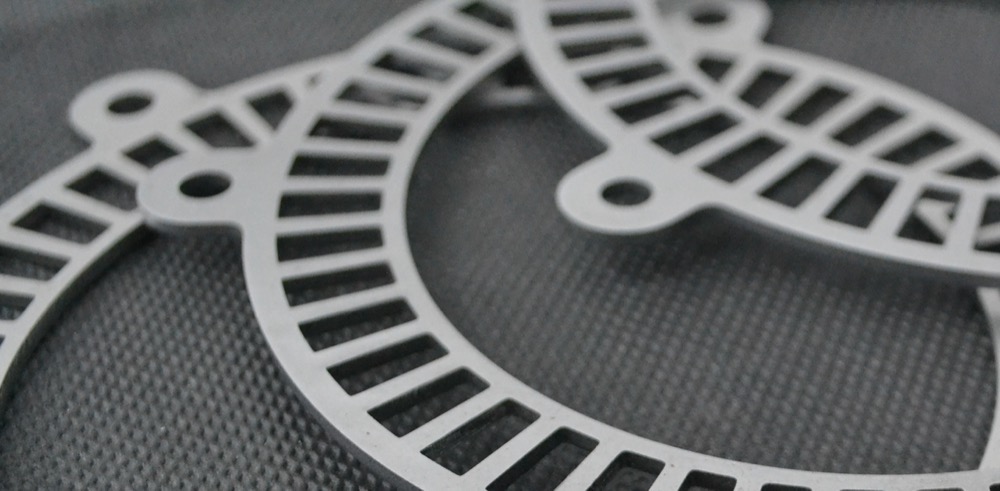

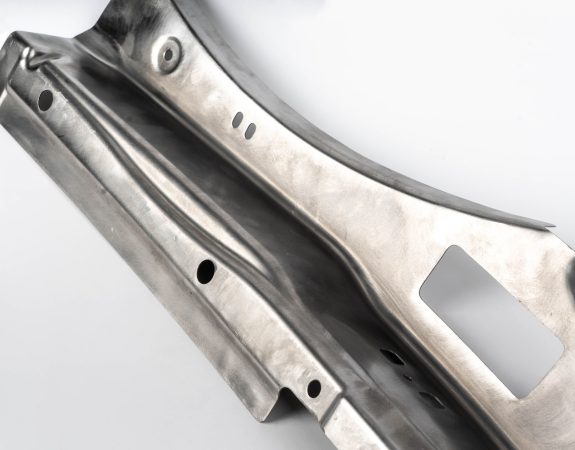

Our rapid sheet metal prototyping and production services include a variety of tooled and manual manufacturing techniques and processes enabling us to realise some highly complex parts without expensive and time-consuming production tooling. We can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal fabricated parts and prototypes.

| Our Capabilities | Sheet Metal Fabrication |

| Max sheet size | 1500 × 3000mm (59.1 × 118.1 inches) |

| Lead time | From 5 days |

| Precision tolerance | ±0.05mm |

| Techniques | 35+ processes |

| Quantity | 1 – 100,000 parts |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

With no minimum order quantity (MOQ), we can support one-offs, small batch and mid-to-high volume production runs. Providing the flexibility and scalable capacity that your sheet metal project requires.

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Anodizing | All metals, primarily Aluminium | Clear, black, grey, red, blue, gold | Increases sheet metal surface hardness, wear resistance, and corrosion resistance, mainly for Aluminium. |

| Bead Blasting | All metals | Uniform matte of raw material colour | Provides a matte or satin finish; mainly for visual texture; available in different grit sizes. |

| Polishing | All metals | Raw material colour, reflective | Mechanical or hand polishing creates a smooth, shiny surface. |

| Powder Coating | All metals | Black, RAL/Pantone Colour | Durable, long-lasting colored finish; tougher and more resistant than painting. |

The table below summarises the standard tolerances used at HLH for sheet metal parts.

| Feature | Tolerance |

| Forming or bending | ±0.508mm (0.020″) |

| Bend to edge | ±0.254mm (0.010″) |

| Bend to hole | ±0.381mm (0.015″) |

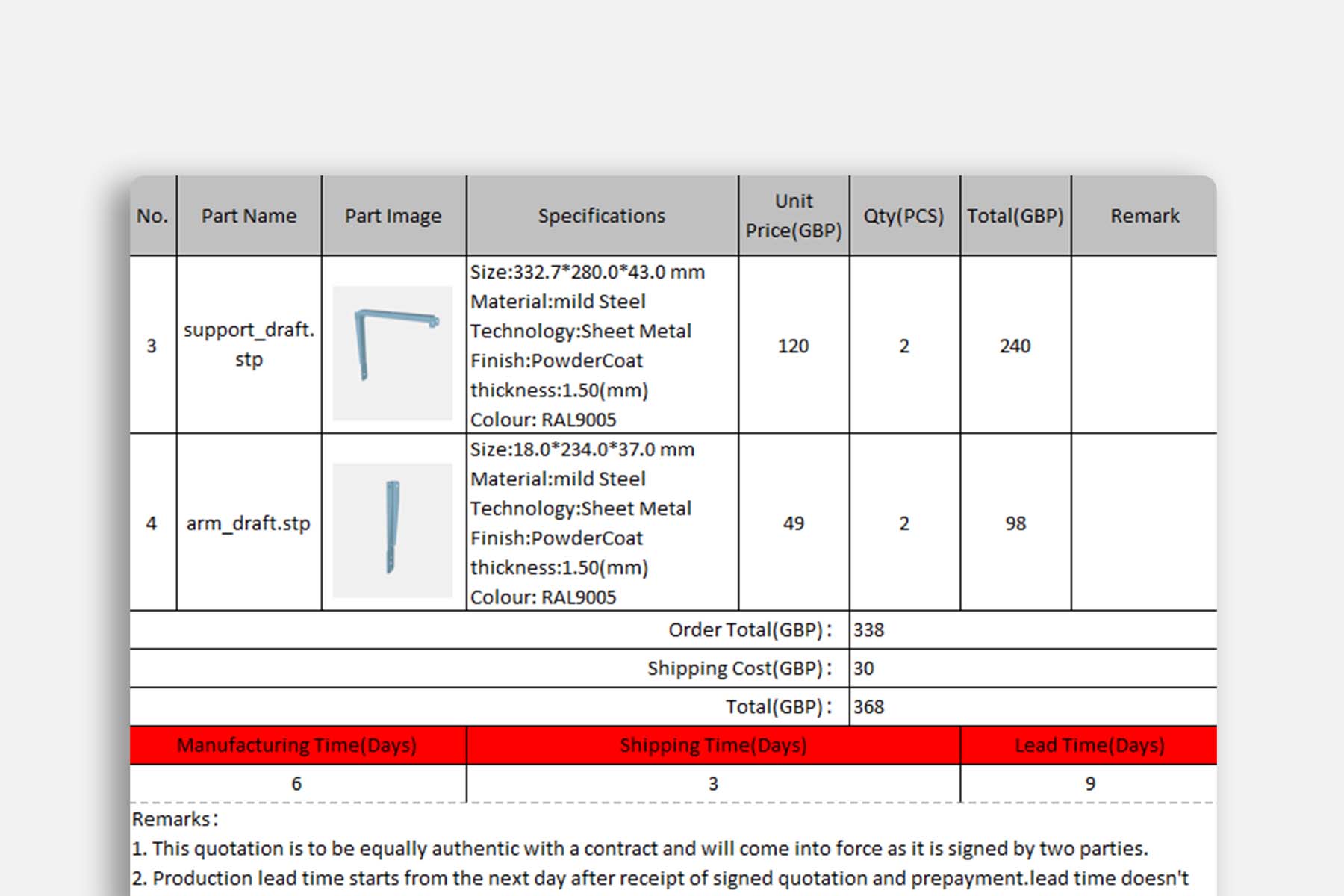

Send us your 3D CAD and include any quantity, material or surface finish requirements, and our team will get back with a quote within 24 hours. What to expect from our comprehensive quote? Sheet metal part price, shipping cost, lead times, and any remarks raised by our engineers.

Designing for sheet metal fabrication can be challenging, as different techniques—such as bending, cutting, and folding—each have their own set of design rules and limitations. For better part quality, learn how to design with the fabrication process in mind.

Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling. Its per-unit pricing lowers significantly in production volumes. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

Sheet Metal Fabrication is Used For

Rapid prototypes, low volume production, medical and communications products, housings and enclosures, everything from cars and space rockets and planes to air conditioners and soda cans.

Advantages of Sheet Metal Prototyping

Sheet metal prototyping is a fast fabrication process used to transform thin sheets of metal into functional parts. It uses a variety of machining processes to cut, form, and assemble sheet metal workpieces, often with minimal tooling. After fabrication, parts usually undergo finishing processes to achieve the desired surface quality and appearance.

Read the Full Guide to Sheet Metal Prototyping for more detailed information about these techniques.

Any metal thinner than 6mm (0.236 inches) is considered sheet metal; any metal thicker than this is classified as a metal plate.

Sheet metal fabrication is a cost efficient and productive way to make thin metal parts, especially enclosures.

Typically, a custom sheet metal prototype or parts can cost anywhere from $5 to $450 and up. The price largely depends on the raw material cost, number of steps involved, size, part complexity and cost of labor. Certain techniques, like sheet metal bending and shearing, tend to be more affordable, while laser cutting or CNC punching can increase the cost due to higher precision and setup requirements.

Many industries are heavily reliant on sheet metal parts. Some top applications include: