Vacuum Casting—ideal for creating a small series of parts, especially when aesthetics are important.

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

Vacuum casting sometimes referred to as Urethane casting or Polyurethane casting, is a perfect solution for production quality parts without the cost or lead time required for production tooling. At HLH, we have a massive range of plastic materials available, and we can cast parts as large and small, everything from headphones all the way up to 2m (2000mm) long car bumpers.

| Our Capabilities | Description |

| Maximum build size | 1.8 x 1.5 x 1.2 m |

| Typical mould life | 10 – 25 parts |

| Tolerance | ±0.05mm/100mm |

| Materials | wide range of resins (see list below) |

| Typical lead time | from 5 days |

| Finish Type | Applicable Materials | Result | Description | Typical Applications |

|---|---|---|---|---|

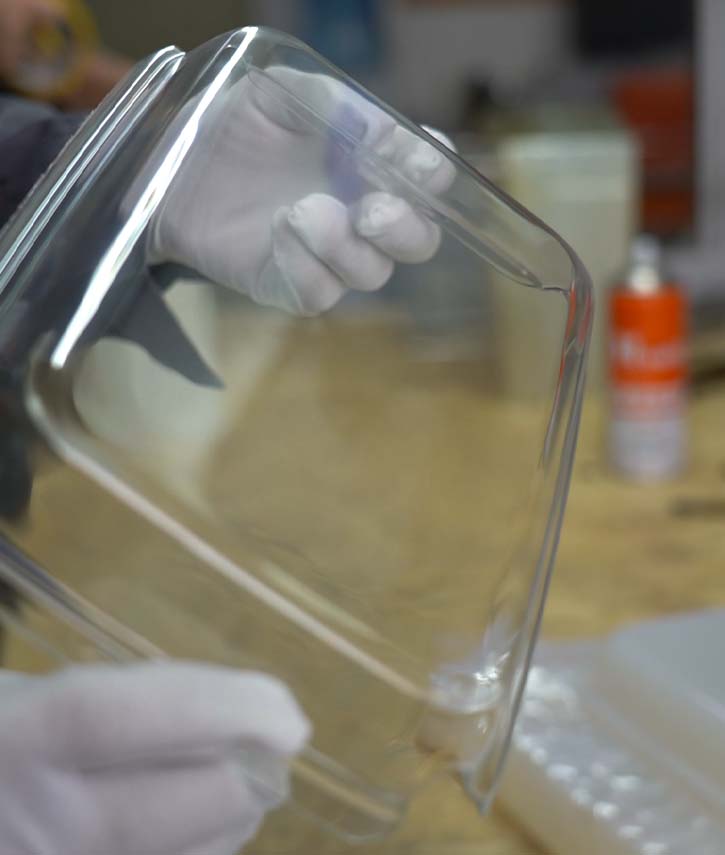

| Transparent | PMMA-like, PC-like | High polish, transparent | Achieves good PMMA- or PC-like transparency. | |

| Glossy | ABS-like, PMMA-like, PC-like | Smooth, shiny | A shiny or reflective surface finish that is extremely smooth. Achieved with a polished master or high-gloss paint/coating. | Control panels, smart speaker shells, parts needing high-end visual effects |

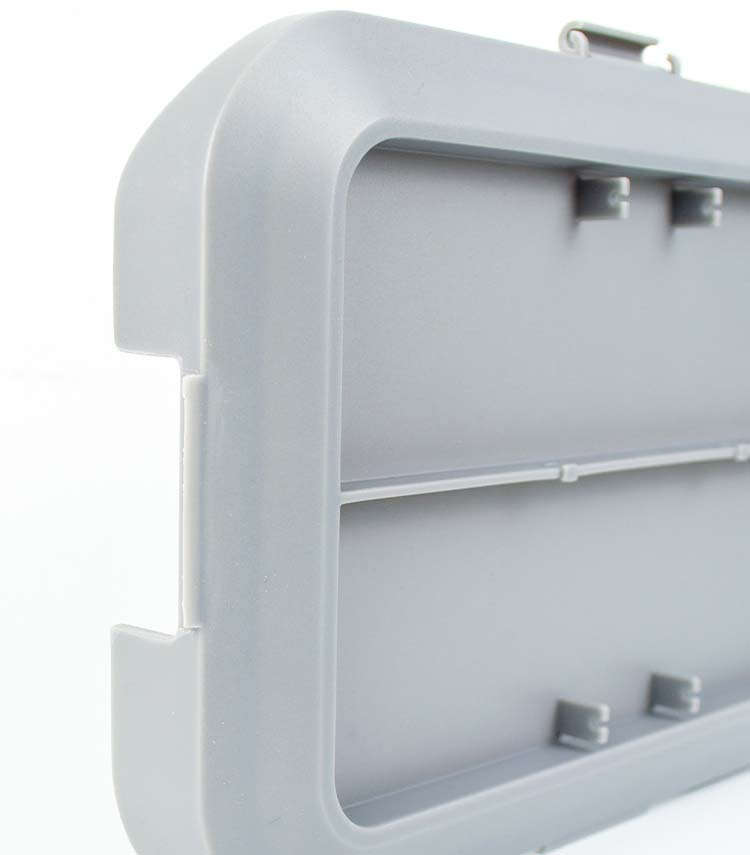

| Matte | Most vacuum-cast urethane materials | Smooth but not glossy | Dull, non-reflective finish. Achieved from matte/textured master pattern or as-cast surface. | Functional housings, industrial components |

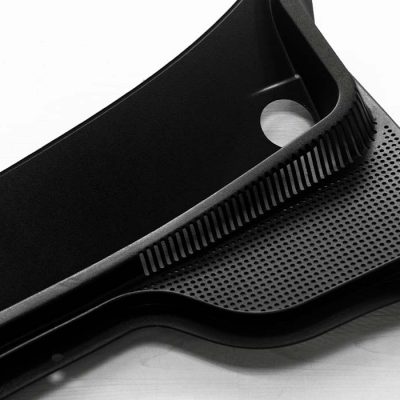

| Textured | Most vacuum-cast urethane materials | Similar to VDI 24–38 | Custom surface texture on the master, replicated in mould for grip or decorative effects. | Grips, handles, automotive panels |

At HLH, standard tolerances are controlled to ISO 2768 Coarse (C) for urethane casting.

| Dimensions (mm) | 0 — 25 | 25 — 50 | 50 — 75 | 75 — 100 | 100 — 125 | 125 — 150 |

| Tolerance (mm) | ±0.3 | ±0.35 | ±0.4 | ±0.45 | ±0.5 | ±0.55 |

Technology Overview

About the Vacuum Casting Process

Vacuum casting (also known as urethane casting, polyurethane casting, cast urethane, and silicone molding) is a fabrication method that uses silicone molds to produce production-quality plastic parts.

The vacuum casting process involves three main stages:

1. Building a master model using 3D printing (via SLA or SLS) or CNC machining.

2. Building the silicone tool by pouring liquid silicone around the master model then curing it.

3. The resin is poured into the cavity to create a production-like replica.

Typical Applications

Vacuum casting is ideal for:

Design For Vacuum Casting

If you are familiar with designing parts for injection moulding, you can apply the same best practices and rules of thumb to design parts for urethane casting. But with some shrinkage considerations. To ensure your design is good fit for vacuum casting and for better results, Learn Actionable Design Tips here.

Vacuum Casting vs Plastic Injection Moulding

Vacuum casting produces parts with similar properties to plastic injection moulded parts. Injection moulding demands a higher front-end cost and a lower unit price, whereas vacuum casting offers a lower front-end cost with a higher unit price. This makes urethane casting a more cost-effective choice for developing early prototypes before creating end-use injection moulded parts.

Advantages of Vacuum Casting

Vacuum Casting refers to the use of the original template to make a silicone mold under vacuum, and use PU material for pouring under vacuum, thereby cloning the same copy of the original template. Read the full process guide here.

The advantages of vacuum casting have made it a choice for many applications across different industrial sectors, including:

Typically used for quantities between 10 to 50 parts, urethane casting is a quick and cost-effective alternative to 3D printing. Especially when it comes to manufacturing large-sized parts, vacuum casting is often much faster and cheaper than 3D printing.