Professional DMLS and SLM 3D printing services for industrial applications

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

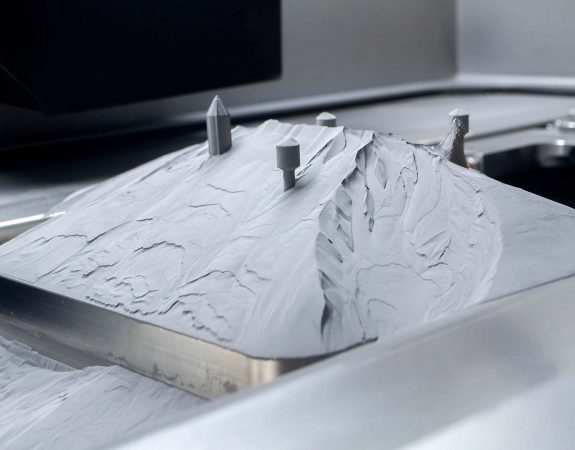

Direct Metal Laser Sintering or DMLS is an industrial metal 3D printing technology. It is a powder bed fusion process similar to SLS, which builds parts from a range of metal materials one layer at a time by sintering metal powders together.

DMLS 3D printing is a process capable of building highly complex shapes which would be near impossible to make via other methods. This technology promises to have a massive range of applications as it improves and becomes better understood.

| Maximum Build Size | 280 x 280 x 280 mm (11″ x 11″ x 11″) |

|---|---|

| Materials | Aluminium, Stainless Steel, Copper |

| Minimum Wall Thickness | 1 mm |

| Lead Time | 5 days |

| Resolution | ± 0.3mm |

| Prototyping Applications | Complex-shaped functional prototypes |

| End-Use Applications | Low volume functional end-use parts |

.jpg)

.jpg)

.jpg)

| Applicable Materials | Colour | Description | |

|---|---|---|---|

| Sanding | All | – | Sanding DMLS printed parts is a good way of smoothing edges, minimizing visible layers, and getting rid of any leftover support marks. |

| Spray Painting | All | Black, Pantone/RAL colours | Spray painting is a quick way to colour DMLS parts. It can also reach areas that cannot be reached with a brush. |

| Plating | All | – | Polishing is often used to enhance the appearance of an item, create a reflective surface or prevent corrosion. |

DMLS and SLM can produce accurate parts to 0.1mm. Achieve even tighter tolerances with our in-house cnc machining services while benefitting from the design freedom of additive manufacturing.

To achieve better part quality and dimensional accuracy, it is important that your 3D model closely follows a set of geometric recommendations. Learn actionable design tips for DMLS and SLM.

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology that uses lasers to fuse powdered metals into functional prototypes and low-volume end-use parts.

Efficiency

Metal printing defies traditional Design-For-Manufacturing guidelines, so designs that would typically be made in assemblies can be made in a single piece.

Complex Geometries

DMLS and SLM produces parts that cannot be made using traditional manufacturing techniques.

Rapid Turnaround

Metal 3D printed parts do not require tooling which reduces the manufacturing lead time from weeks to days, allowing for faster innovation and speed to market.

Production Parts

SLM and DMLS utilizes powdered metals with strong mechanical and dynamic properties, making it perfect for end-use parts.

Direct Metal Laser Sintering, or DMLS, is an additive manufacturing technology that produces functional metal prototypes and low-volume production parts by melting and fusing layers of metallic powder together through a high-power laser beam.

Ultimately, Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), often used interchangeably, are very similar additive manufacturing processes. They both use laser energy to add metal powder together rapidly. The main difference is that SLM heats the metal powder until it fully melts into a liquid, whereas DMLS just sinters heat particles enough so that their surfaces weld together.

Yes. At HLH, we offer both DMLS and SLM 3D printing services. We are able to produce complex-shaped and functional metal alloys or pure metal prototypes and low-volume end-use parts.