Multi Jet Fusion (MJF) is an additive manufacturing (AM) technology comparable to Selective Laser Sintering (SLS). It is capable of printing highly complex industrial parts and prototypes with a high level of precision and with consistent isotropic mechanical properties.

To help achieve better part quality and dimensional accuracy, it is important that your 3D model closely follows a set of geometric recommendations. This article offers an overview and considerations of the MJF process, best design practices, and weight-saving and cost-reduction design tips and tricks.

MJF uses an inkjet array similar to that of a color 2D printer to selectively fuse a bed of powdered material (mainly nylon) into a solid layer. The process repeats layer by layer until the final part is complete. Like SLS, MultiJet Fusion belongs to the powder bed fusion 3D printing category; hence, it does not need any support structures, allowing for greater design freedom.

MJF Process Considerations

| Maximum Build Size | 380 x 285 x 380mm |

|---|---|

| Resolution | ±0.3mm |

| Dimensional Accuracy | ±0.3% (with a lower limit of ±0.3 mm) |

| Materials | PA11, PA12 |

| Surface Structure | Rough |

| Support | Not required |

Wall Thickness

MJF walls that are designed too thin are at high risk of warping. We recommend a wall thickness of at least 1mm. Avoid overly thick walls, as they can lead to an uneven pockmarked surface.

Assembly Parts

Adequate clearances must be designed to prevent the assembly from fusing together into a single solid part. To avoid this, we recommend leaving a minimum gap of 0.9 mm between mating parts.

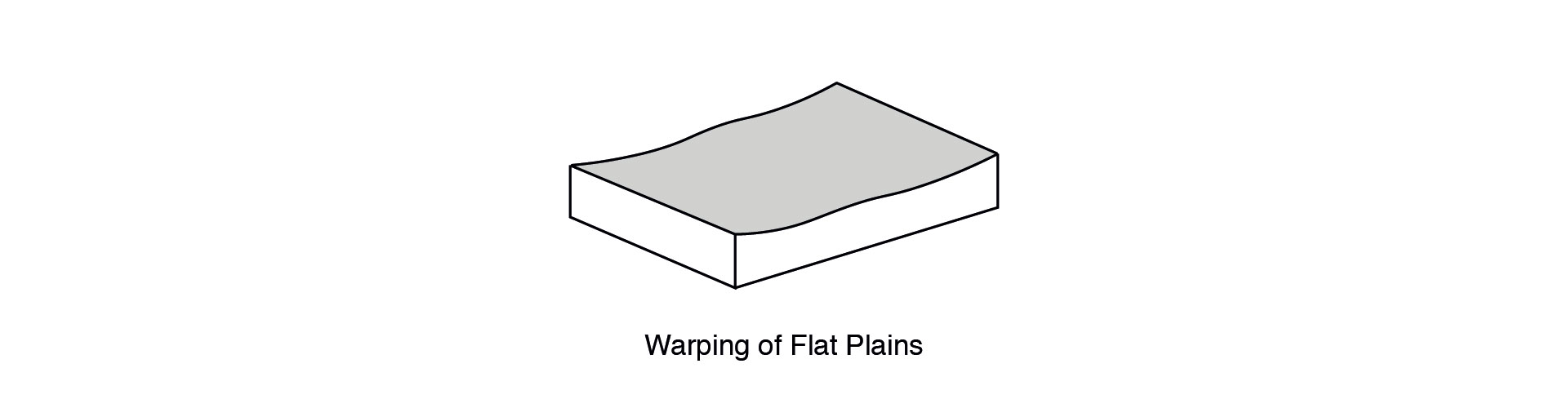

Flat Surfaces

Large, flat plains are susceptible to warping. To avoid this, ribs can be added to crucial features, however, this may not always solve the problem. Hence, it is recommended to such features whenever possible. Consider replacing solid-volume areas with lattice structures or designing short planes with sufficient part thickness (at least 0.3mm).

Lattice Structures

Adequate clearance is needed in lattice structure designs to enable easy removal of residual material inside the part. The recommended minimum gap size in a lattice structure is 1 mm.

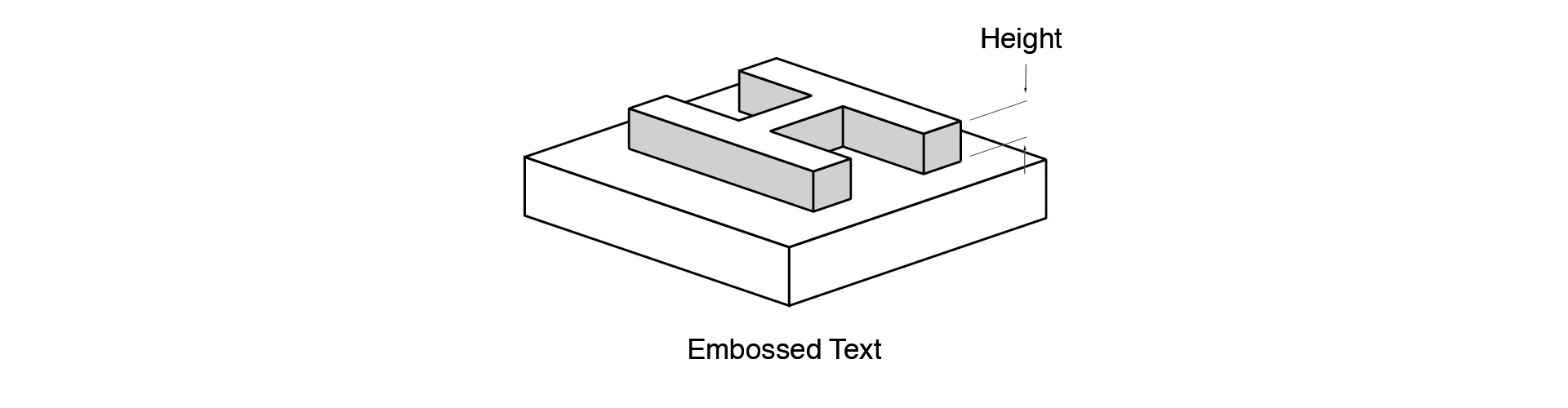

Embossed Features

Embossed features must be designed using a minimum height to ensure visibility and to prevent the detail from wearing off during post-processing. We recommend a minimum height of 0.5mm. To ensure such details come out nicely, make them larger than the indicated.

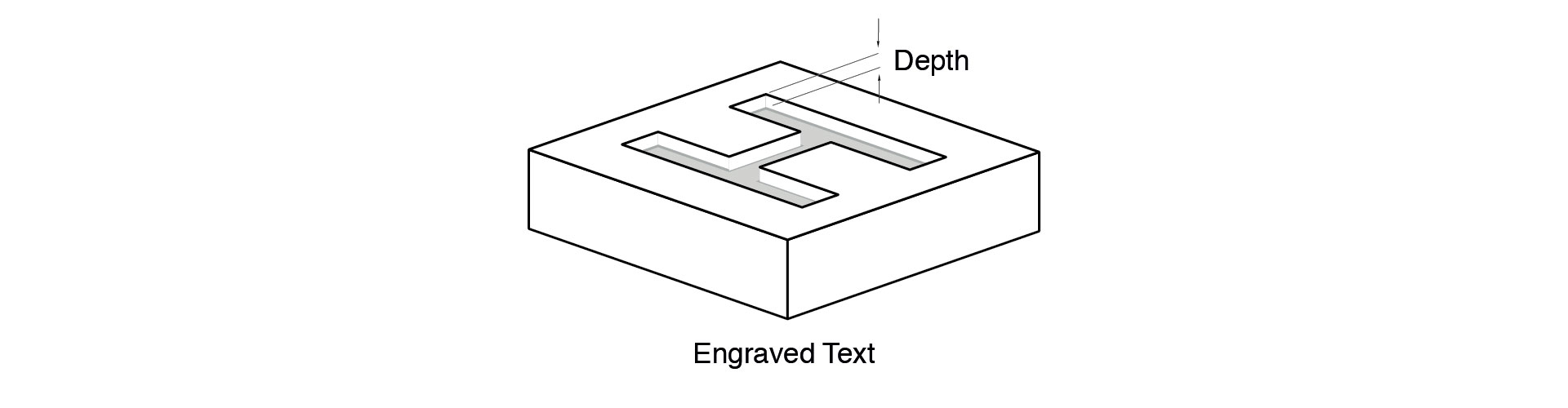

Engraved Features

With MJF, text and engraved details are at risk of closing up and won’t appear visible if not designed with a minimum depth and width. We recommend a minimum depth of 1mm and width of 1mm.

| Wall Thickness | At least 1mm thick; avoid overly thick walls |

|---|---|

| Assembly Parts | Minimum gap of 0.9mm |

| Flat Surfaces | At least 0.3mm thick; avoid large, flat plains |

| Lattice Structures | Minimum gap of 1mm |

| Embossed Features | Minimum height of 0.5mm |

| Engraved Features | Minimum depth of 1mm; minimum width of 1mm |

It is worth noting that SLS is often a better option than MJF for more solid parts; however, for lower density parts, MJF generally costs less. This section outlines weight-saving solutions/designs that can help reduce the overall cost of your MJF part.

Use this 3D Printing Design Guidelines when designing your MJF parts for machining, then export your 3D CAD files in an STL format. Have your designs ready? Submit your designs now to get a FREE quote. Our team of 3D printing experts are always available to provide on-hand support and recommendations to ensure your parts are print ready.