Leverage 25+ years of vast CNC machining expertise, parts as fast as 4 days.

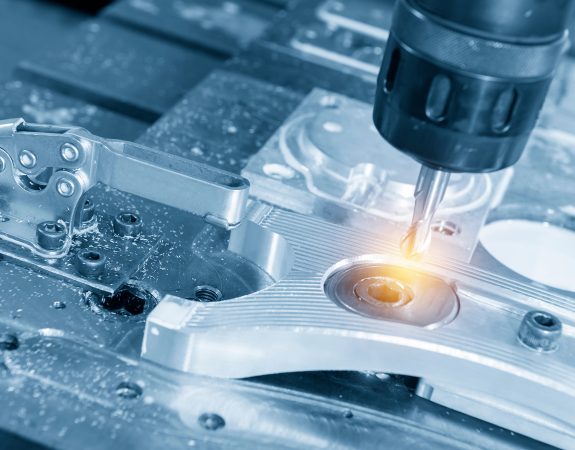

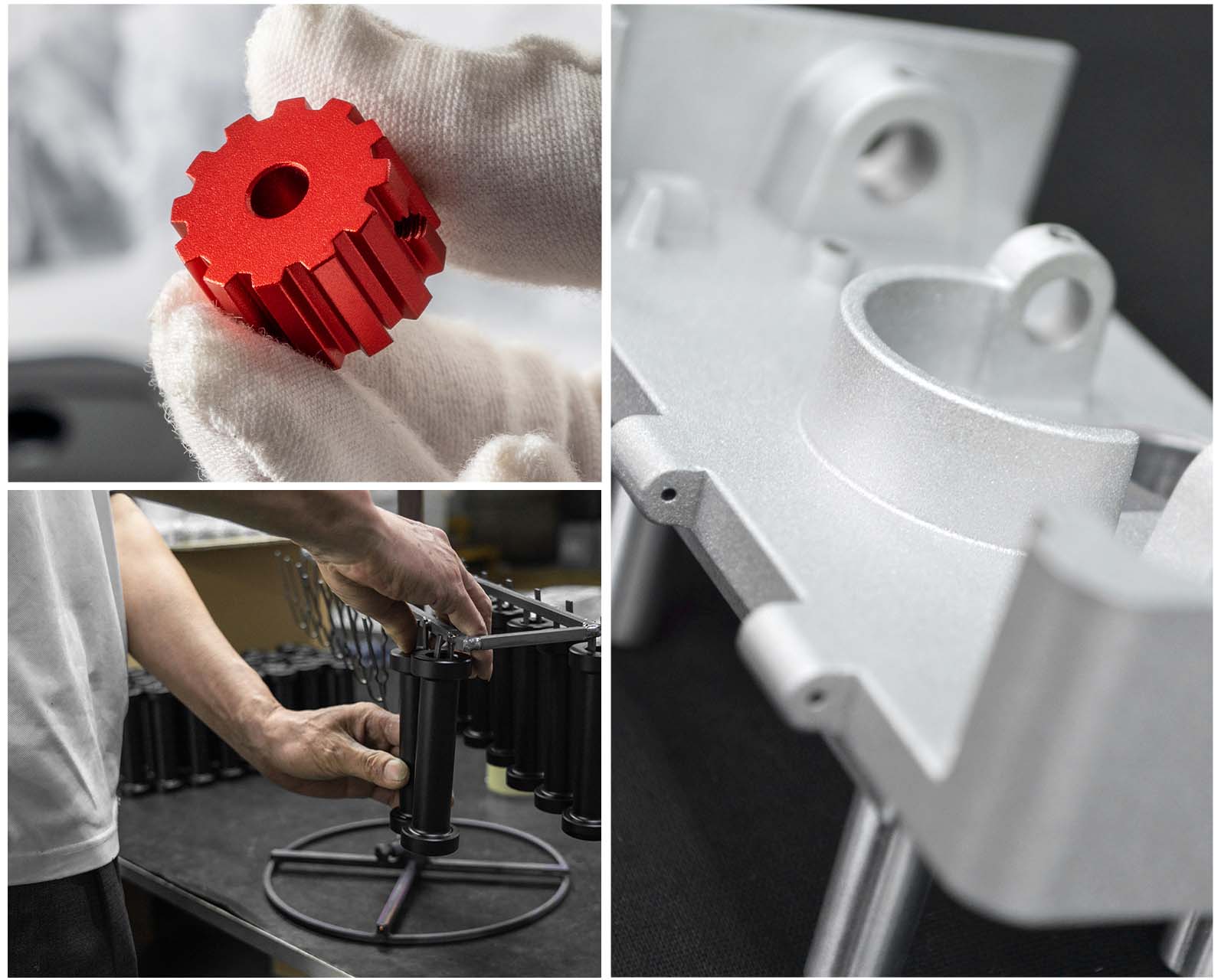

Our Custom CNC Machining Services is ideal for engineers and industrial designers seeking high-speed, high-precision parts. At HLH Rapid, we offer CNC services suitable for rapid prototyping and low-volume production of end-use components. With a dedicated facility housing over 150 high-tech CNC mills, lathes, wire EDMs, countersinks, and surface grinding machines, along with quality assurance at every stage, we ensure the finest quality components tailored to your exact specifications.

| Our Capabilities | Description |

| Machine size | 3000 x 1200 x 850 mm |

| On-site machines | 100+ |

| Materials | 200+ metals, plastics, carbon fibre |

| Standard tolerance | ±0.05mm (metals), ±0.2mm (plastics) |

| Lead time | From 4 days |

Get a quote / Get in touch

Please use the following formats:

.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf and .zip

100mb max file size (per file)

If you have a file type not listed, please contact us to discuss first.

Home Office: 116 Cardigan Road, Office M2.

Headingley, Leeds UK, LS6 3BJ

Company Number: 12704810

VAT Number: GB393458263

Factory: Building A, Hongfa Industrial District

Houda Road, Daling Shan, Dongguan,

Guangdong, China

.JPG.jpg)

We have 15+ high quality chemical and mechanical finishing options available for CNC metals and plastics.

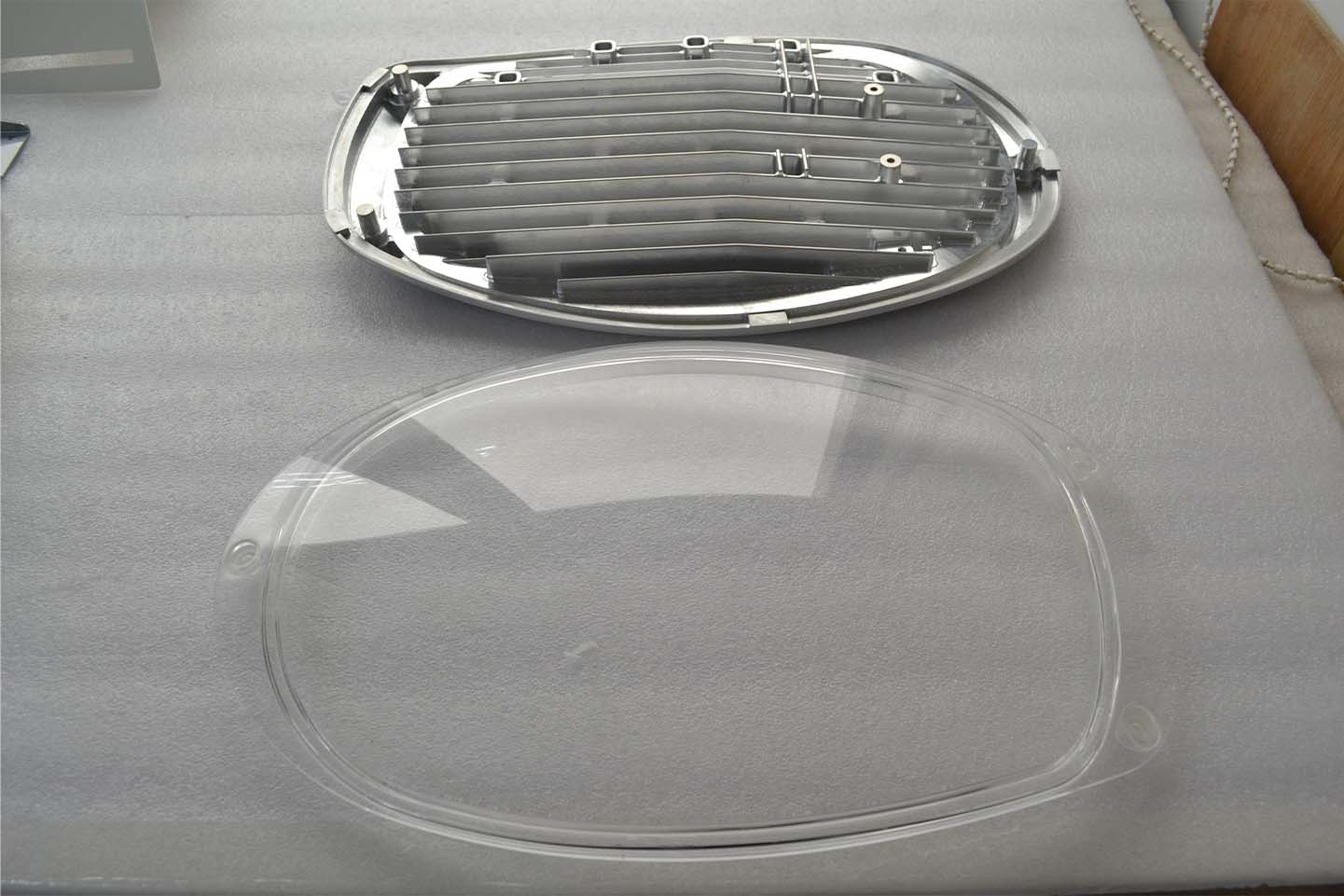

| Client | Smartflyer, Switzerland |

| Industry | Electric aviation |

| Services used | CNC milling & turning |

| Materials | Al7075, SS304 |

| Parts made | Actuator, bearings, push rods, bellcranks, fuselage mount, rudder mount, etc. |

At HLH, tolerances are controlled to ISO-2678 Fine (F) for metals and Medium (M) for plastics as standard. Tighter tolerances available on request.

| Metals With Drawing | Metals No Drawing | Plastics With Drawing | Plastics No Drawing | |

|---|---|---|---|---|

| Linear Dimension | ±0.01mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

| Hole Diameters | ±0.008mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

| Shaft Diameters | ±0.004mm | ISO 2768 Fine | ±0.05mm | ISO 2768 Medium |

To achieve better part quality and dimensional accuracy, it is important that your CNC model closely follows a set of geometric recommendations. Learn how to design threads, cavities, internal edges and more.

We understand the needs of engineers and industrial designers. At the core of our mission is a commitment to deliver excellence. HLH Rapid’s full in-house capacity ensures that each CNC project receives prompt attention, whether it’s a bespoke prototype or a low volume production. Trust us to bring your designs to life with thorough attention to detail and dedication to meeting deadlines.

One of our areas of expertise is CNC Rapid Prototyping & CNC Machining Services. We understand the urgency and importance of prototyping in product development. When you upload your file, our team will get back with a quote within one business day. Our rapid prototyping services guarantee swift turnaround times without compromising on quality, with lead times as fast as 4 days, and parts delivered via express shipping to your door.

CNC vs 3D Printing

Compared with parts manufacturing through additive methods, CNC machined parts are functionally stronger and typically have superior production quality and finish. Thus, CNC machining is typically used in the mid to late stages of product development when parts are ready to be tested for functional accuracy.

Custom CNC Machining is Used For

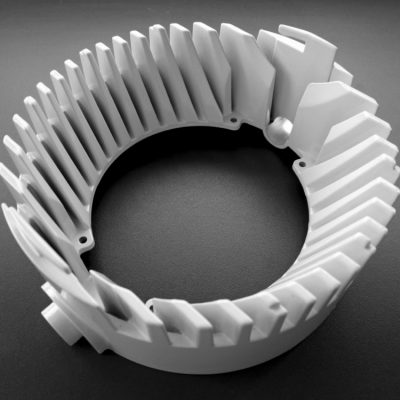

High precision parts and rapid prototyping metal parts, performance plastics, and rapid low-mid volume production runs. When it comes to CNC machining, we provide highly flexible rapid low volume manufacturing solutions that deliver superior parts, fast.

Advantages of CNC Machining

CNC (or computer numerical control) machining is a subtractive manufacturing process in which pre-programmed software and code dictates the movements of factory tools and machinery. It delivers high speed, high precision, and robust manufacturing solutions. You take a block or billet of material and cut away at it with a series of tools and drill bits, removing material to make CNC machined parts.

CNC prototyping uses computer-controlled machines to make precise prototypes from digital designs. These machines carve out shapes from materials like plastic, metal, or wood based on the design. Starting with a digital model, the CNC machine follows exact instructions to create the prototype, ensuring high accuracy and intricate details.

Unlike traditional prototyping methods, CNC rapid prototyping allows for iterations within days. This process speeds up product development by allowing quick testing and adjustments before making the final product. Industries like automotive, aerospace, medical and electronics use CNC prototyping to test concepts, refine designs, and ensure quality before mass production. It’s a vital step that brings ideas to life, improving products and meeting high standards.

CNC parts could cost from as low as a few dollars, or as high as $1000 or more. The price depends on the material, tolerance, machining hours, geometrical complexity, part size or quantity. Learn how suppliers calculate the cost of your CNC part.

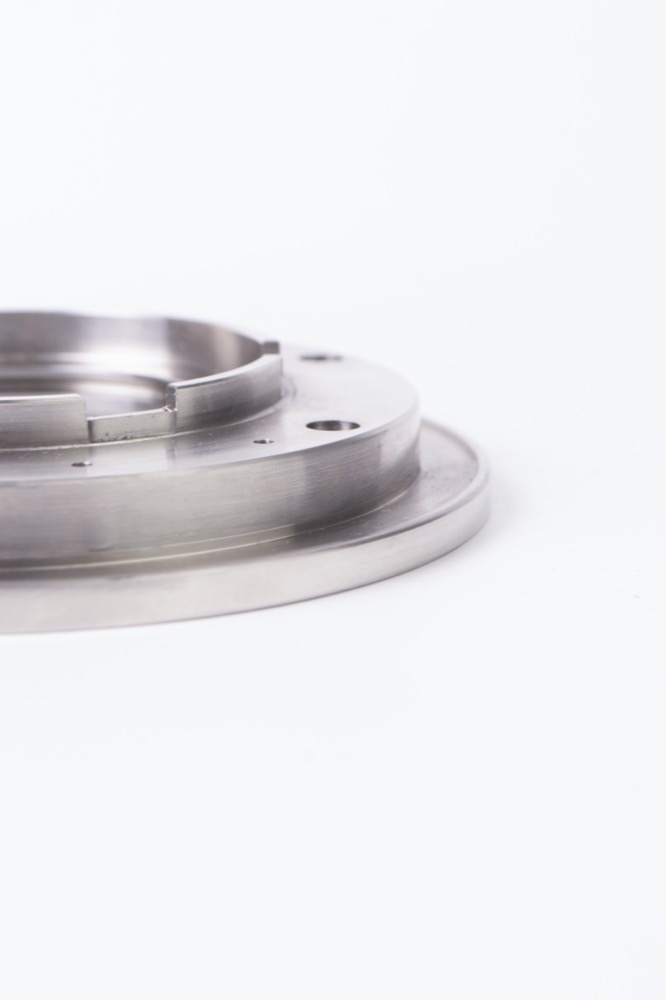

The two primary CNC machining processes are CNC turning and CNC milling.

At HLH, we use a third CNC machining process known as EDM or electrical discharge machining.

Many industries rely on CNC machining for high-precision parts and prototypes, including:

For features left unspecified, standard tolerances are used. The standard machining tolerance is ISO 2768 Fine (F) for metals and Medium (M) for plastics. Tighter tolerances are available on request.

Generally, we would recommend CNC machining parts over 3D printing, as CNC machined parts are functionally stronger than those 3D printed and typically have superior production quality. This is why CNC machining is typically used in the mid to late stages of development, when parts are ready to be tested for functional accuracy.